Out of the ashes rises great opportunity. That is the theme of the new exhibit “Creation from Catastrophe — How Architecture Rebuilds Communities” at the Royal Institute of British Architects. Featuring a number of impressive projects dedicated to rebuilding communities after a disaster, the exhibit explores the evolving relationship between man, architecture, and nature.

In an interview with Dezeen magazine, curator Jes Fernie said the exhibit reveals an “expanded idea of what architecture is and what architects can do.”

From Floating Schools to Unseen Plans for an Alternative London, a New Exhibition Showcases the Good, the Bad and the Ugly Architectural Responses to Urban Disasters

The exhibit, which opened on Jan 27 and runs through April 24, spans nearly four centuries riddled with successful disaster relief projects. It features designs for rebuilding after London’s Great Fire in 1666 as well as plans for water communities in Nigeria, which could be affected by unpredictable coastal water levels in Africa’s near future.

Here are five other unique projects you can follow up on when visiting the Catastrophe exhibit this spring:

1. The Reliance Building, Atwood, Burnham and Co., North State Street, Chicago, 1890-1895

While devastating, Chicago’s Great Fire of 1871 paved a new way for architectural design. Considered by many to have birthed the Chicago School architectural style, the disaster also led to a new type of architectural design: the skyscraper.

In an effort to create fire-retardant buildings, designers utilized tools such as steel frames and sheet glass coverings. The Reliance Building, constructed by Atwood, Burnham, and Co, is one of the first post-fire buildings that fathered a design very similar to the modern day skyscrapers we know.

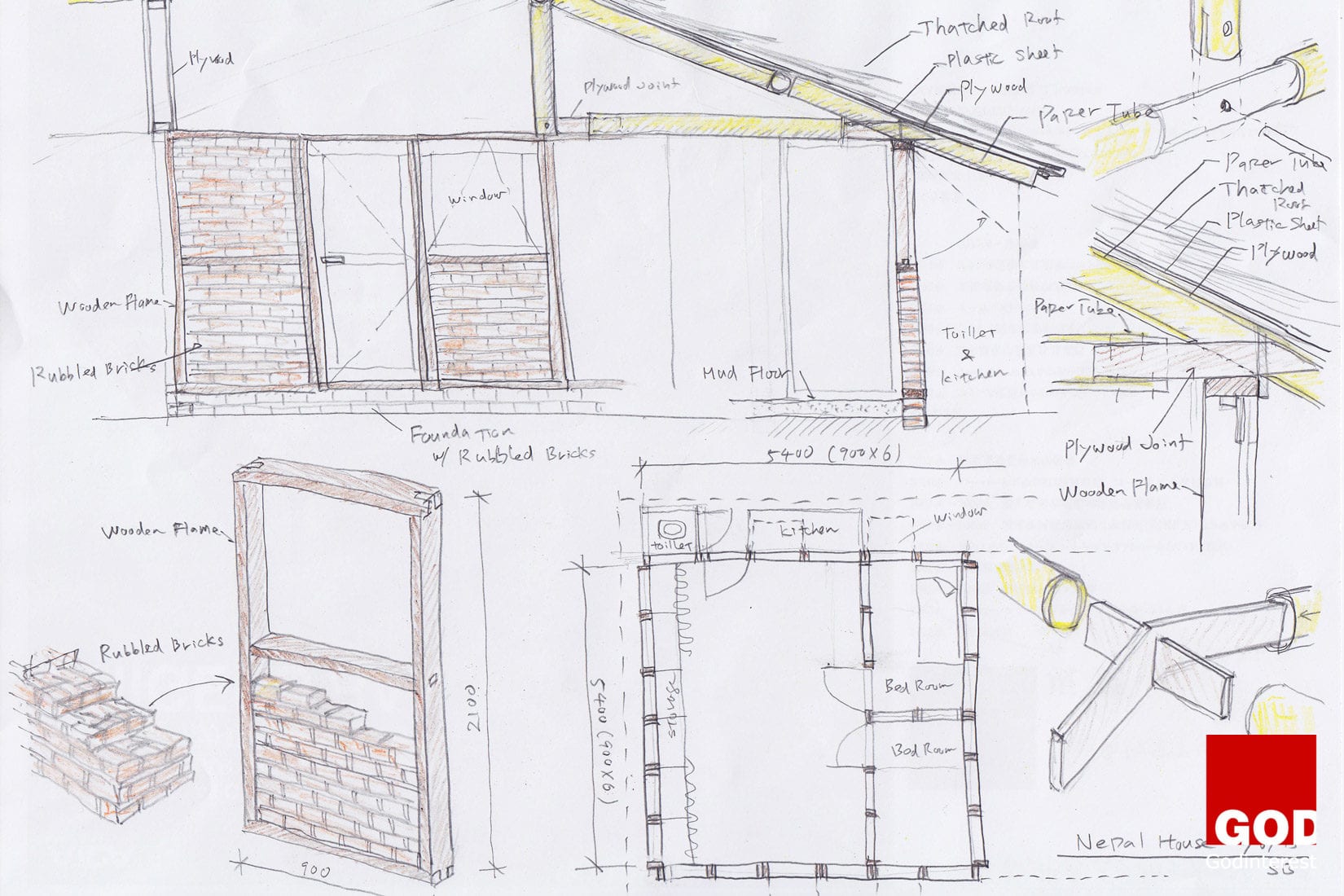

2. Housing for Nepal earthquake victims, Shigeru Ban, 2015

Simple, traditional homes in Nepal were the ones that withstood the catastrophic earthquake in 2015. As a result, Pritzker Prize-winning, disaster-relief architect Shigeru Ban designed housing structures for the victims.

Ban’s modular housing concept is modelled on the traditional homes that survived the earthquake. His design uses wood frames for the structure, cardboard tubes for the truss system of the roof, and debris from the disaster as infill for the wall. Thatch and plastic sheeting provided an extra layer of protection on the rooftop.

3. Women’s Centre in Darya Khan, Pakistan, Yasmeen Lari, 2011

Pakistani architect Yasmeen Lari (the first woman architect in Pakistan) showcases architecture’s role and influence in society. Throughout her career, the 75-year-old designer has built over 36,000 homes for earthquake and flood victims throughout Pakistan. She is also the founder of Heritage Foundation of Pakistan, which allows architecture students to train local residents to rebuild their homes and communities after a disaster using natural resources like bamboo and mud.

One of her well-known projects includes the Women’s Centre in Darya Khan, Pakistan. Lari holds a deep affection for Pakistani women, who are typically displaced and struggling with the care of their children following a natural disaster. The layout allows women to unite and socialize and keep their children safe. And in the event of a flood striking, the first floor is high enough so that waters cannot reach it.

4. Post-tsunami sustainability plan for Constitución, Chile, Elemental, 2014

After 2010’s deadly earthquake shook the coastal cities of Chile, plans for rebuilding and protecting cities like Constitución became a priority. In an effort to work with nature and the community, Pritzker Prize-winning architect Alejandro Aravena’s firm Elemental, proposed the intriguing method to plant more trees along the coast to absorb waters and prevent flooding.

The idea is that there is an opportunity to do something that would have long-term positive impacts, rather than a temporary fix that might be ruined by another major earthquake or tsunami in the area. The project will hopefully address short-term needs as well as potential long-term problems.

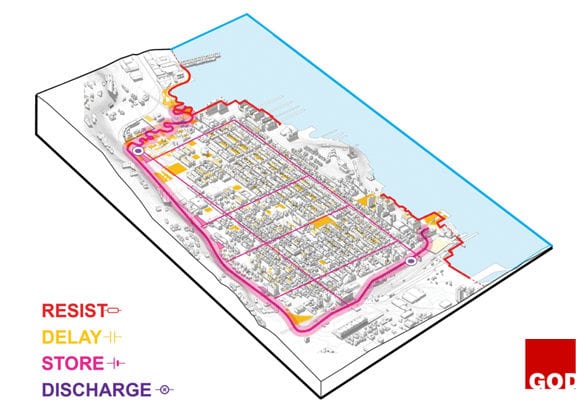

Resist. Delay. Store. Discharge. A Comprehensive Urban Water Strategy

5. Rebuilding of Hoboken, New Jersey after Hurricane Sandy, OMA, 2012

Following the disastrous Hurricane Sandy that struck the Northeastern United States in 2012, about 80 percent of Hoboken, New Jersey homes were flooded, leaving the community wondering how to rebuild itself with an emphasis on flood defense.

That’s when Dutch architect Rem Koolhaas’ firm OMA offered a solution that would combine hard infrastructure and soft landscaping, integrating coastal defense and natural drainage to protect against future flooding. The ideas between OMA’s and Elemental’s projects are very similar in that they look to work with nature rather than avoiding it.

Fernie told Dezeen that OMA offers a multi-pronged approach: resist, delay, restore and discharge. It acknowledges the complex water system and works with it, he said.

Curved surfaces can make a small space even smaller. The ability to organise the rooms vertically is reduced. But Dutch architects Queeste Architecten have managed to give this 320-square-foot micro-flat a spacious feel using lots of white, with built-in furniture and storage.

Curved surfaces can make a small space even smaller. The ability to organise the rooms vertically is reduced. But Dutch architects Queeste Architecten have managed to give this 320-square-foot micro-flat a spacious feel using lots of white, with built-in furniture and storage.