Concrete Proves Its Versatility Is Endless

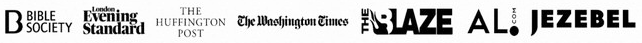

Professor Pavel Matousek – Laser Man

Professor Pavel Matousek, a Science and Technology Facilities Council (STFC) Senior Fellow and Chief Scientific Officer of Cobalt Light Systems Ltd, has pioneered revolutionary techniques for analysing the chemical composition of materials and co-founded a highly successful spin-out company. He has helped develop and commercialize award-winning laser technologies that detect liquid explosives at airports, rapidly check the quality of pharmaceutical products, and that may one day non-invasively diagnose breast cancer. Pavel states:

“I Am Very Excited about What I Do and Driven to Answer Questions in Front of Me, Unravel Complex Problems and Deliver Something Useful to Society.”

STFC science writer James Doherty meets the Laser Man.

Pavel, what first got you interested in physics?

I became fascinated by the stars and Universe while growing up in the Czech Republic. I joined an astronomy society at secondary school and it became clear I wanted to study physics. I got very interested in laser physics during my MSc at the Czech Technical University in Prague. It is a very dynamic field.

When did you arrive at Rutherford Appleton Laboratory (RAL)?

I joined as a research associate in 1991, and went on to complete my PhD in ultra-fast Raman Spectroscopy at RAL, awarded by the Czech Technical University. I’ve been here almost 25 years to the day.

So what is Raman Spectroscopy?

It is a technique that involves shining a laser beam at the surface of a material, and then observing the colour of light scattered from the point of illumination. This typically provides information about the chemical composition of the material’s surface. C.V. Raman observed the effect in 1928 and subsequently won a Nobel Prize.

You pioneered a technique called Spatially Offset Raman Spectroscopy (SORS): What is it and how does it differ from normal Raman Spectroscopy?

“We couldn’t have developed the SORS technique without the instrumentation and long term research continuity available at the Central Laser Facility at RAL”

SORS is a technique that we stumbled across in the Ultrafast Spectroscopy Laboratory (ULTRA) by chance. We had assumed that photons could only be detected at the illumination point but we were wrong. Some photons migrate sideways through the material then emerge adjacent to the illumination point. As these photons have interacted with molecules deeper inside the medium, they provide information about internal chemical make-up: SORS probes deeper into the material. And the further you move from the illumination point, the deeper you see into the medium. The process

involves large photon migration distances, often extending to several centimetres or more. This came as a big surprise.

“SORS involves probing at one location and detecting at another. Our minds, and those of others, were constrained by our perception of how the Raman Spectroscopy process worked but once we made this serendipitous discovery, we quickly realised it had potential major applications.”

What kind of applications?

“The Range of Potential Applications for Sors Is Staggering.”

We immediately realised SORS could determine the chemical make-up of substances by non-destructive means. This could have applications in bio-medicine, chemistry, security, forensics, heritage, and beyond. But we first focused on pharmaceuticals, and developed novel ways for analysing the chemical make-up of manufactured drugs.

We swiftly filed 8 patents, which became the basis of our company Cobalt Light Systems.

Cobalt Light Systems is perhaps best known for its airport security scanners. Can you describe how these work and their impact to passenger travel?

Security scanners represent the second generation of technology developed by Cobalt. To date there are around 400 operational units in 70 airports across Europe and Asia. They are used to scan traveller essentials, such as medicines or baby milk, and compare their chemical make-up to a database of potentially explosive substances. Suspicious substances are automatically identified and flagged. For example, the technology avoids passengers having to drink liquids (e.g. baby milk) in front security officer to prove they are not dangerous, which is clearly safer and more hygienic. It has also contributed to new legislation, and is expected to lead to a relaxation of the complete ban of taking liquids on board a plane in the future.

The scanners are currently the size of a microwave oven but right now we are launching a SORS handheld device. This should have further applications for first responder teams called to spillages of unknown substances and fire fighters attending chemical fires.

Pavel Matousek Pioneered a Technique Called Spatially Offset Raman Spectroscopy (SORS)

How did STFC help with this process?

First off, we used instrumentation at STFC’s Central Laser Facility to demonstrate the basic capability to detect the SORS subsurface signal. Once we made the discovery in 2004, we worked closely with STFC’s Technology Transfer Office SIL (formerly CLIK) and Business and Innovations (BID) to develop, optimise and protect our ideas. There was a complex path to navigate from discovery, to optimising SORS, building a prototype, and ultimately to securing investment in 2008. BID/SIL coordinated the company at all levels and provided the support necessary to achieve this goal.

“My story illustrates the national and international importance of STFC. If its determination to deliver impact on science was absent, the chain from a fundamental discovery to Cobalt Light Systems’ product would have been broken. STFC responded appropriately at every stage. And this is just one example of how STFC contributes to the UK’s know-how economy.”

What are you working on currently?

I’m focused on developing novel non-invasive medical screening techniques, including diagnosing bone disease such as osteoporosis (jointly with STFC’s Prof Tony Parker and University College London’s Prof Allen Goodship), and I’m working with Professor Nicolas Stone of Exeter University on non-invasive breast cancer screening.

In addition, I’m collaborating with Consiglio Nazionale delle Ricerche in Italy to apply the SORS technology to objects of art on microscales. For example, we can scan different layers of paint to determine compositional information essential in restoration and preservation of artefacts.

How will the medical applications benefit patients?

Patient benefit could be enormous. Current diagnosis techniques for osteoporosis are around 60-70% accurate as they sense only mineral content. SORS on the other hand has a high specificity for mineral and collagen content – both of which determine bone strength – and so holds considerable promise for providing improved diagnostic accuracy. SORS could also be used to classify breast or prostate tumours as malignant or benign without needle biopsy. This would reduce patient stress and save medical provider costs.

However, medical problems are challenging as the human body is complex and variable. These applications are probably still 7-10 years away.

Why do you do this research?

This is where my passion and interest lies – I’m very excited about what I do.

“As You Push the Boundaries of Technology and Make New Discoveries, the End Goal Always Changes. This Is the Nice Thing about Science.”

Small Projects Often Mean Greater Innovation

Small projects often embody more innovation than larger more costly or high profile ones.

Innovation is a wide concept that includes improvements in processes, products and services. It involves incorporating new ideas which generate changes that help solve the needs of a company and so increase its competitiveness. That’s hardly big news. But what may be surprising to some is that innovation has itself, well, innovated and it isn’t what it used to be.

New materials and energy, design approaches, as well as advances in digital technology and big data, are creating a wave of innovation within the construction industry. These new ideas are increasingly often tested and proven on smaller and agiler projects. Investing time and money is well spent on these ideas and technical improvements can then be used on large-scale developments.

Here are three exciting small projects:

Milan, Italy

1. Vanke Pavilion – Milan Expo 2015

The corporate pavilion for Vanke China explores key issues related to the theme of the Expo Milano 2015, “Feeding the Planet, Energy for Life”.

Situated on the southeast edge of the Lake Arena, the 800-square meter pavilion appears to rise from the east, forming a dynamic, vertical landscape.

The original tiling pattern would have resulted in thousands of ceramic tiles of different sizes and shapes. The resulting complexity and lack of repetition could have led to high costs and a longer erection time.

Working with Architects Studio Libeskind, Format Engineers (Engineering Designers with backgrounds in structural engineering, coding, mathematics, and architecture) changed the pattern from thousands of different tiles to less than a dozen and simplified the backing structure generating huge cost savings. Format Engineers also proposed ‘slicing’ of the building and then fabrication of the primary structure of steel ribs using low tech flat steel plate elements. These were then used in a series of long span portalised frames reminiscent of the ribs and spars in traditional boat building resulting in a column-free area for the display of Chinese Cultural Heritage.

The frame was built to a budget and without difficulty ahead of the neighboring Expo buildings.

Building Size

12 meters high

740 mq gross floor area (exhibition, service & VIP levels)

130 mq roof terrace

Architect: Studio Libeskind

Engineer: Format Engineers

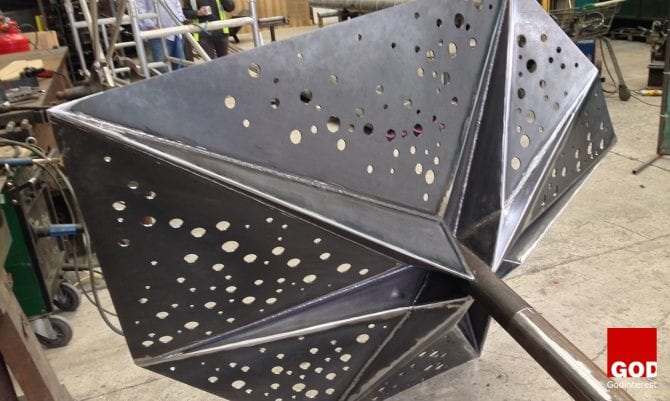

2. Oxford Brookes Rain Pavilion

The Rain Pavilion is an urban forest sculpture forming the front entrance to Oxford Brookes University’s Architecture Faculty.

“Rain Pavilion artwork is a sensory experience for the community.”

The complex form required extensive wind modeling and comprehensive structural analysis within a generative 3d model. This was allied with Format Engineers in-house code for the self-organization of voids and their subsequent redistribution.

.At each stage of the design process different modeling and analysis techniques were used to exploit the form and to optimise the structure. The considerable challenges posed by the slenderness of the structure and its dynamic behavior under wind were resolved by combining Computational Fluid Dynamics (CFD) (a branch of fluid mechanics that uses numerical analysis and algorithms to solve and analyze problems that involve fluid flows) with a generative design environment. Conceptual design introduced the ideas of tubular stems and folded steel canopies, both of which were perforated by circular holes arranged to allow the interplay of light and water through the structure. The voids were generated using a self-organizing process.

Grasshopper (a graphical algorithm computer 3-D modeling tool) was used to produce a mesh that could include the voids in both the stems and the petals.

The Rain Pavilion is designed to celebrate the sound of rain, and the noise of water interacting with different sections of the installation is part of the experience of passing through it. The structure has a design life of five years and can be transported to other locations.

Architect: Oxford Brookes University, Oxford, UK

Engineer: Format Engineers

3. KREOD Pavilion

The KREOD pavilions were first erected on the London Greenwich Olympic site in 2012. Easily rearranged, three pod-like pavilions were formed with a wooden structural framework comprised of an open hexagonal composition.

Standing three meters tall, each double-curved wooden shell enclosed a footprint of 20 square meters, totaling 60 square meters. A waterproof tensile membrane sealed the interior from the elements fully portable with demountable joints, the individual components can be stacked for efficient transportation.

Chun Qing Li the architect required a temporary exhibition or function space that could be erected and demounted mostly by hand and by untrained staff. The quality of finish needed to echo that of handmade furniture and had to be low cost and quick to erect. The continuously changing double curved form of the enclosure meant that in theory, every nodal connection was different. A conventional bolted solution would have cost hundreds of pounds per fixing. Format Engineers suggestion of a ‘reciprocal’ jointed timber grid shell required standard bolts which equated to a fraction of the normal cost. It also allowed the structure to be built from simple and light flat timber elements.

The structure used Kebony timber throughout, a sustainable alternative to tropical hardwood. As this material had not previously been used in a structural context Format Engineers undertook load testing of the material and the connections at the University of Cambridge. The timber was fabricated using CNC routing (a computer controlled cutting machine) allowing a highly accurate fit between members and basic erection on site.

Architect: Chun Qing Li

Engineer: Format Engineers