Dim1, N. U., Okorocha2, K. A., & Okoduwa3 V. O.

The Nigerian construction industry is mostly concerned with the development and provision of projects such as roads, bridges, railways, residential and commercial real estates, and the maintenance necessary for the socio-economic developments contributes immensely to the Nigerian economic growth (Bureau of Statistics, 2015). Butcher and demmers (2003) described projects as an idea which begins and ends by filling a need. However, a project fails when its idea ends without meeting the needs and expectations of its stakeholders.

Nigeria Has Become the World’s Junk – Yard of Abandoned and Failed Projects worth Billions of Naira!

Hanachor (2013), revealed that projects form part of the basis for assessing a country’s development. However, a damming report from the Abandoned Projects Audit Commission which was set up by the Ex-President Goodluck Jonathan in 2011 revealed that 11,886 federal government projects were abandoned in the past 40 years across Nigerian (Abimbola, 2012). This confirmed the assertion by Osemenan (1987) “that Nigeria has become the world’s junk –yard of abandoned and failed projects worth billions of naira”.

Abandoned projects including building and other civil engineering infrastructure development projects now litter the whole of Nigeria.

Physical projects do not only provide the means of making life more meaningful for members of the community where the projects are located, successful projects also result in empowerment and collective action towards self improvement (Hanachor, 2013).

This Issue of Abandonment Has Been Left Without Adequate Attention for Too Long, and Is Now Having a Multiplier Effect on the Construction Industry in Particular and the Nigeria’s National Economy as a Whole. (Kotngora, 1993)

PROJECT FAILURE

Project Failure might mean a different thing to different stakeholders. A project that seemed successful to one stakeholder may be a total failure to another (Toor and Ogunlana, 2008). Some stakeholders, more especially the project users and some private owners, think of failed projects as a situation where a completed building project collapsed, a situation where by a completed dam project stopped working after few days of completion, or a completed road project that broke down after few months of completion. Other experienced stakeholders, such as engineers and architects conform to the iron triangle by Atkinson (1999) which states that the most strategically important measures of project failure are “time overrun”, “cost overrun”, and “poor quality”.

Turner (1993) noted that a project fails when the project specifications are not delivered within budget and on time; the project fails to achieve its stated business purpose; the project did not meet the pre-stated objectives; the project fails to satisfy the needs of the project team and supporters; and the project fails to satisfy the need of the users and other stakeholders. Lim and Mohamed (1999) cited in Toor and Ogunlana (2009) clarified that there are two possible view points to project failure namely; the macro-level and the micro-level. They further explained that the macro view point reviews if the original objectives and concepts of the project was met. Usually the end users and the project beneficiaries are the ones looking at the project failure from the macro view point, where as the project design team, the consultants, contractors, and suppliers review projects from a micro view point focusing on time of delivery, budget, and poor quality.

In the early 1990s, the failure as well as the success of any project was determined by the project duration, monetary cost, and the performance of the project (Idrus, Sodangi, and Husin, 2011). Belout and Gauvrean (2004), also confirmed that the project management triangle based on schedule, cost, and technical performance is the most useful in determining the failure of a project. Moreover, a project is considered as an achievement of specific objectives, which involves series of activities and tasks which consume resources, are completed within specifications, and have a definite start and end time (Muns and Bjeirmi 1996, cited in Toor and Ogunlana, 2009). Reiss (1993) in his suggestion stated that a project is a human activity that achieves a clear objective against a time scale. Wright (1997) taking the view of clients, suggested that time and budget are the only two important parameters of a project which determines if a project is successful or failed. Nevertheless, many other writers such as Turner, Morris and Hough, wateridge, dewit, McCoy, Pinto and Slevin, saarinen and Ballantine all cited in Atkinson (1999), agreed that cost, time, and quality are all success as well as failure criteria of a project, and are not to be used exclusively.

FACTORS OF PROJECT FAILURE

Cookie-Davies (2002) stated the difference between the success criteria and the failure factors. He stated that failure factors are those which contributed towards the failure of a project while success criteria are the measures by which the failure of a project will be judged. The factors constituting the failure criteria are commonly referred to as the key performance indicators (KPIs).

Time and Cost Overrun

The time factor of project failure cannot be discussed without mentioning cost. This is because the time spent on construction projects has a cost attached to it. Al-Khali and Al-Ghafly, (1999); Aibinu and Jagboro, (2002) confirmed that time overrun in construction projects do not only result in cost overrun and poor quality but also result in greater disputes, abandonment and protracted litigation by the project parties. Therefore, focus on reducing the Time overrun helps to reduce resource spent on heavy litigation processes in the construction industry (Phua and Rowlinson, 2003). Most times, the time overrun of a project does not allow resultant system and benefits of the project to be taking into consideration (Atkinson, 1999). Once a project exceeds the contract time, it does not matter anymore if the project was finally abandoned or completed at the same cost and quality specified on the original contract document, the project has failed. Furthermore, Assaf and Al-Hejji, (2006) noted that time overrun means loss of owner’s revenue due to unavailability of the commercial facilities on time, and contractors may also suffers from higher over heads, material and labour costs.

Poor quality/Technical Performance

The word “Performance” has a different meaning which depends on the context it is being used and it can also be referred to as quality. Performance can be generally defined as effectiveness (doing the right thing), and efficiency (doing it right) (Idrus and Sodangi, 2010). Based on this definition of performance, at the project level, it simply means that a completed project meets fulfilled the stakeholder requirements in the business case.

CAUSES OF PROJECT FAILURE

A lot of research studies have investigated the reasons for project failures, and why projects continue to be described as failing despite improved management. Odeh and Baltaineh, 2002; Arain and Law, 2003; Abdul-Rahman et al., 2006; Sambasivan and Soon, 2007; all cited in Toor and Ogunlana, 2008, pointed out the major causes of project failures as Inadequate procurement method; poor funding and availability of resources; descripancies between design and construction; lack of project management practices; and communication lapses

The contract/procurement method

A result obtained from two construction projects which were done by the same contractor but using different procurement methods showed that rework, on the design part which occurs when the activities and materials order are different from those specified on the original contract document, makes it difficult for the project to finish on the expected time (Idrus, Sodangi, and Husin, 2011). This is as a result of non-collaboration and integration between the design team, contractor, and tier suppliers. The rework on the design portion has a huge impact on project failure leading to the time overrun. The traditional method of procurement has inadequate flexibility required to facilitate late changes to the project design once the design phase of the construction project has been concluded.

Nigerian most widely used procurement method is the traditional method of procurement (design-bid-construct) which has been confirmed to be less effective to successfully delivery of a construction project (Dim and Ezeabasili, 2015). And, the world bank country procurement assessment report (2000) cited in Anigbogu and Shwarka, (2011) reported that about 50% of projects in Nigeria are dead even before they commence because they were designed to fail.

The way the construction projects are contracted, in addition to the way the contracts are delivered, contributes to the causes of projects failure. Particularly, among the methods of project contracting is lump-sum or a fixed-price contracting method, in which the contractor agrees to deliver a construction project at a fixed price. The fixed-price contract can be low-bid or not however, once the contract cost has been agreed upon the contract award, it cannot be changed. And, contractors are expected to honor and deliver the contract agreement, failure to do so can result in a breach of contract which can result in the contractor being prosecuted.

Awarding a contract to an unqualified personnel also contributes to project failures. When a contractor places more emphasis on money and the mobilization fee after a construction project has been initiated instead of getting the right workforce and skilled professionals that will execute the project. Instead the workforce chosen will often not be base on competence and required skills rather it will be based on availability. Moreover, poor strategy and planning by contractors who have overloaded with work also contributed to one of the causes of project failure.

Poor funding/Budget Planning

A lot of public projects in the Nigerian construction industry failed as a result inadequate funding, and the difference between the national annual budget and the budget actual released. Most of the Nigerian public projects are signed even before the actual release of the national budget. The difference in budget of the contracted project and the actual budget release can get the contracted company stuck as a result of inflation of prices, scarcity of construction material at the time of the budget release and mobilization to site. Also un-planned scope of work which can be as a result of the contractor working on another contract when he is called back to mobilization to start work. Moreover, poor budget planning is a regular mistake made by some contractors by not undertaking feasibility assessments before starting the design. The construction project should be planned according to the available resources and not according to the unrealistic expectations a client has in mind.

Discrepancies Between the Design and Construction

Limited collaboration between the contractors, engineers, and the architect results in discrepancies between the project designs and construction on site, and further leads to rework. Changes on a project designs, and changing to the scope of work in the middle of construction processes on site can be dangerous, and can lead to time overrun, increase in cost, and most of all can lead to abandonment. Moreover, many cases have been seen where the designs from the architects are not buildable on site, while In some cases, most contractors are unable to adequately specify the scope of work for the construction processes on site. Therefore any default on the design by the architect can be an opportunity for the contractor to make more money which might cause the project duration to exceed the time specified on the contract document.

RESEARCH METHODOLOGY

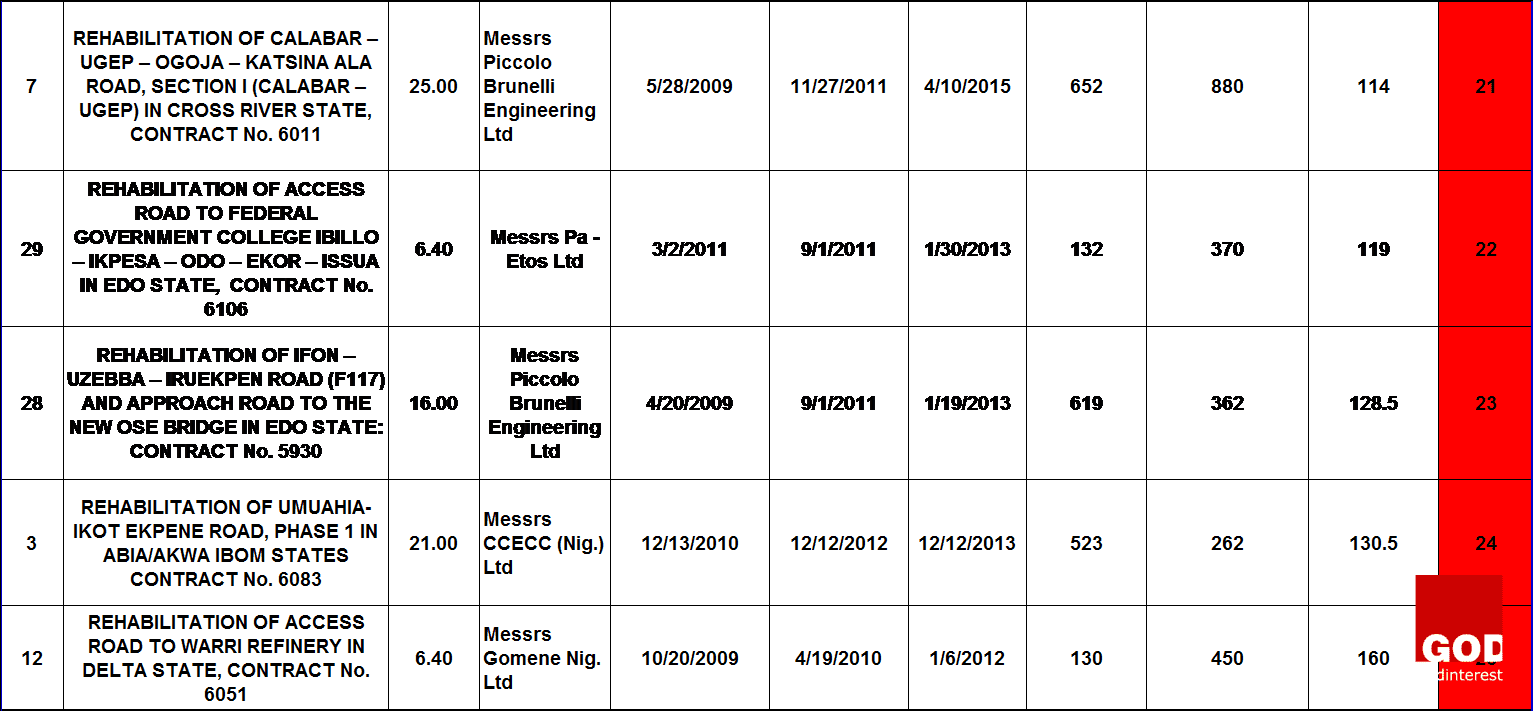

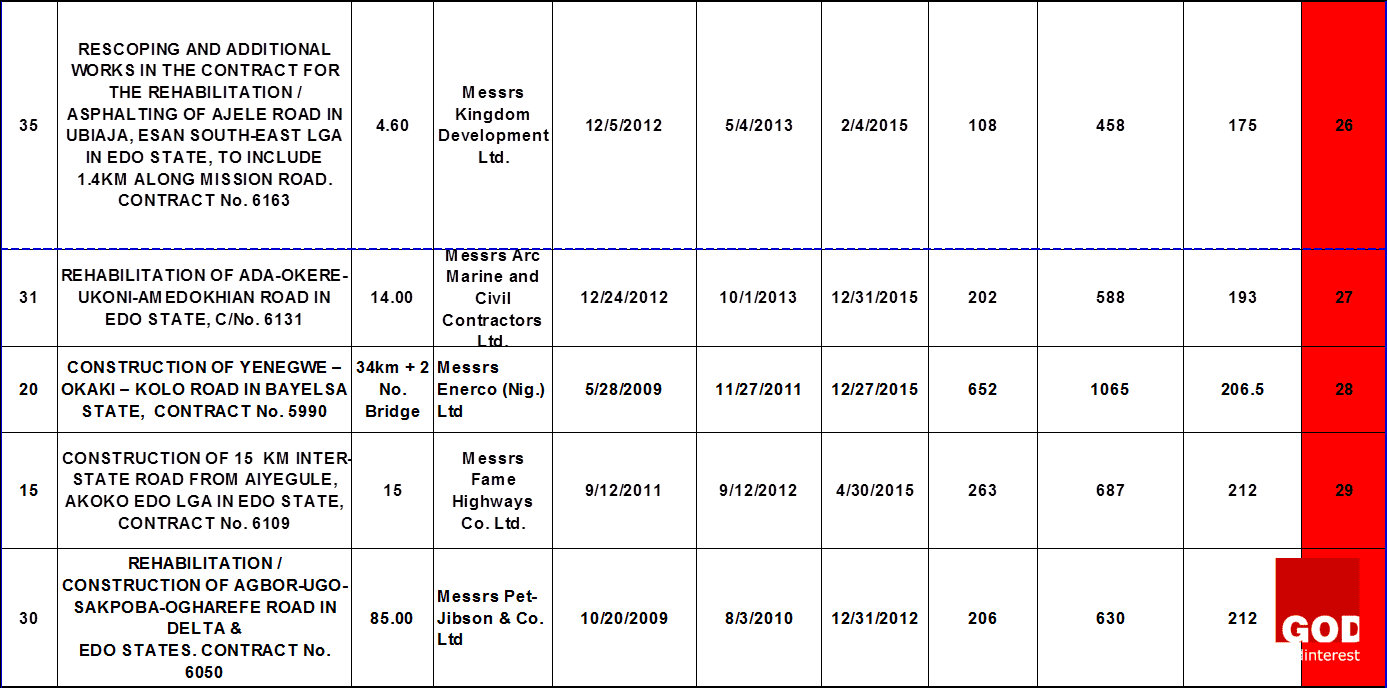

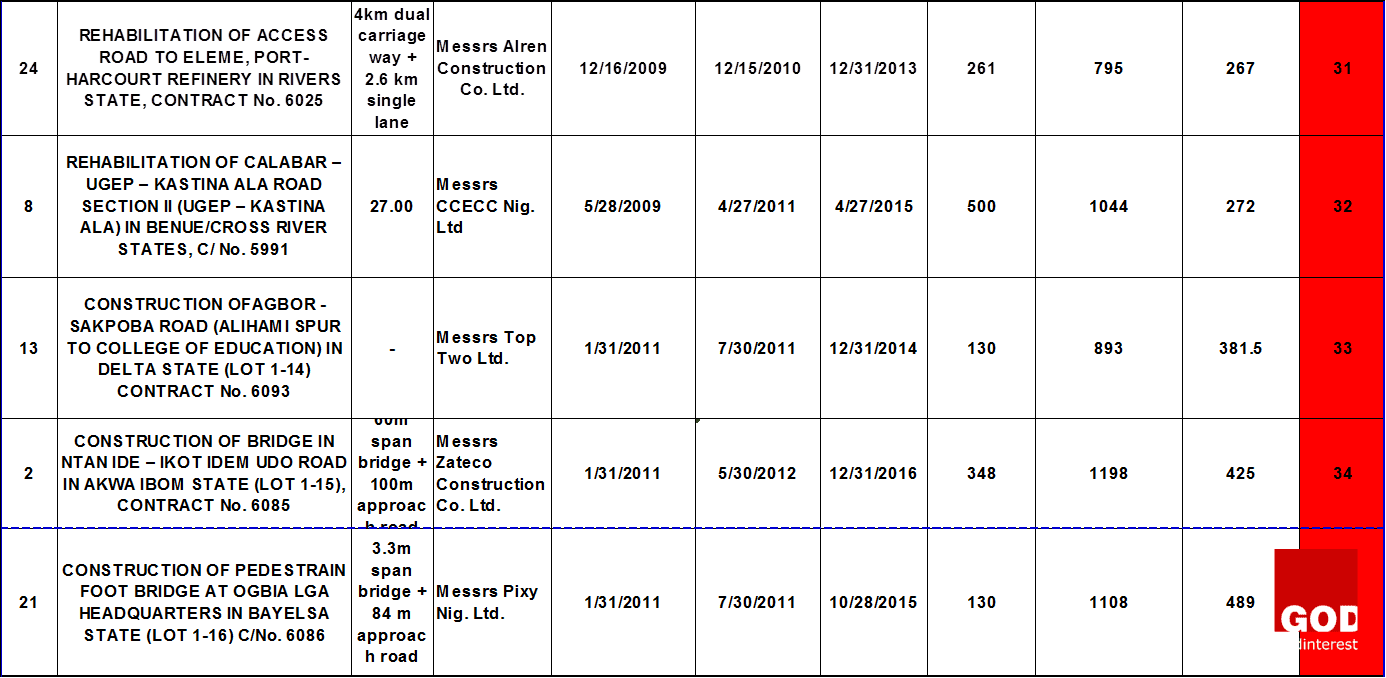

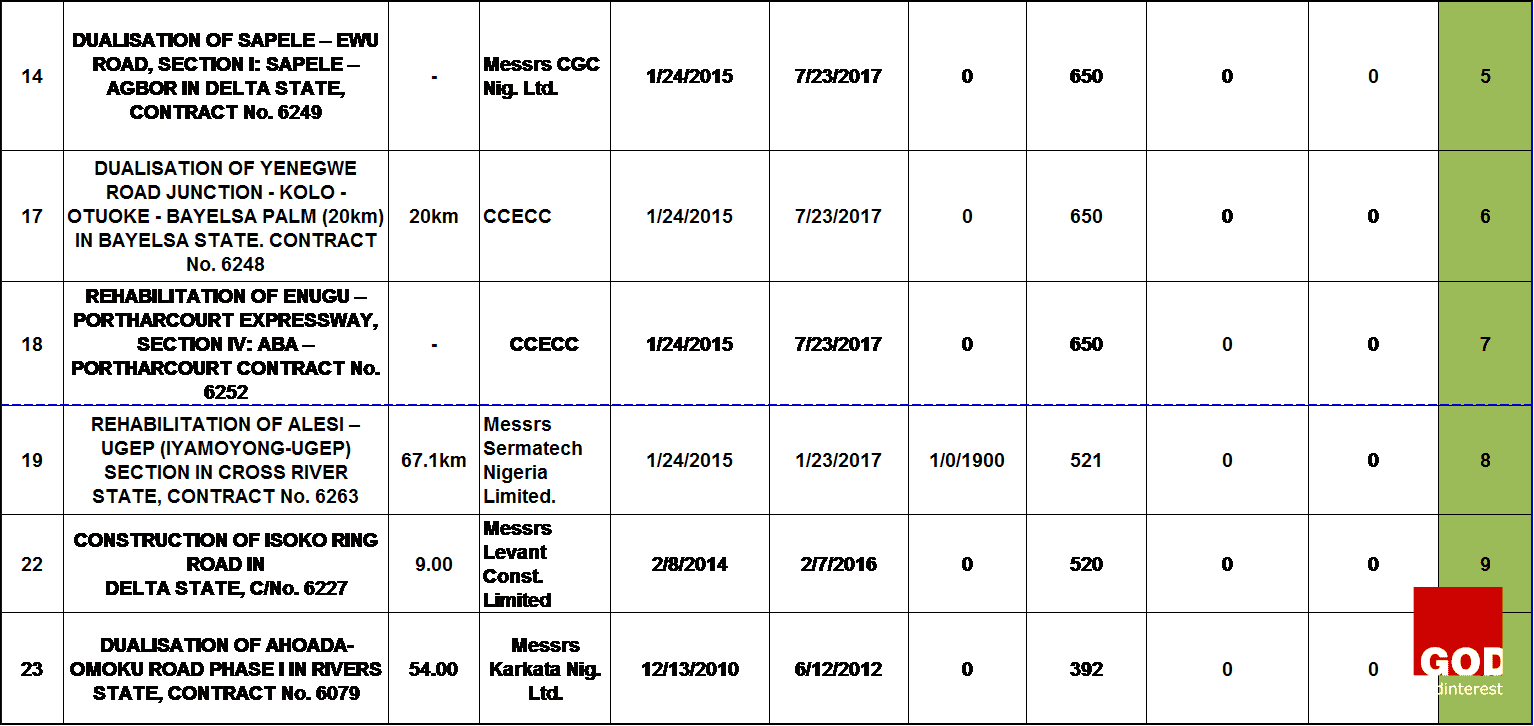

This research starts with a general reasoning or theory which says that the major cases of project failure in the Nigerian construction industry are defined based on time overrun and cost overrun. The findings from the data analysis will help on the decision to accept the theory or not. The research data was collected from the progress report for the month ending of October, 2015 published by the Nigeria of Federal Ministry of works on thirty-nine on-going highway construction projects at the South-South geopolitical zone. The table 1 below shows the information on the data collected which comprises of the project title, contract Number, project description, the contractor that was awarded the projects, the date of project commencement, date of completion and the extended date if any. The scheduled time for each project was specified as follows: project commencement date labeled as “a”, project completion date labeled as “b”, and the extended date labeled as “c”.

DATA ANALYSIS

The data analysis was done with the use of Microsoft excel. The analysis started by obtaining the number of days between the date of commencement of each project and the date of completion to show the duration of each highway project. And, the number of days between the project completion date and the extension date showed the time-overrun. The project duration and the extended days were obtained with the use of NETWORKDAYS function in Microsoft Excel which calculates the number of working days between two dates excluding weekends and any dates identified as holidays.

The standard deviation between the specified project duration for each highway projects and the extended days was calculated to obtain the extent to which each highway project contract failed on its time of delivery. This was denoted as the degree of failure. The table 1 above showed the projects ranking which was done based on the degree of failure of all the highway projects. The highway projects that were ranked from one to sixteen have low degree of failure and are represented with green color, while the rest are those with high degree of failure and are represented with red color.

FINDINGS

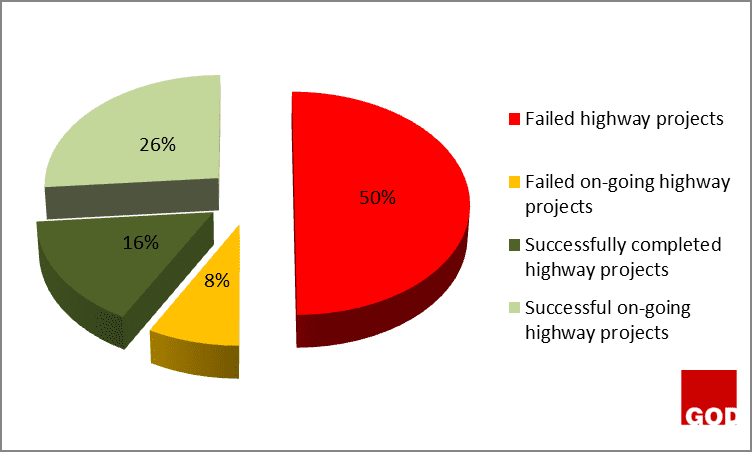

The findings made showed that the successfully completed highway projects have no extended days or time overrun, and the successful on-going highway projects are still on schedule and have no extended days unlike the on-going highway projects that have already failed as a result of the extended dates. Other projects have been abandoned because they have exceeded the delivery date as specified on the contract document, and have no extended date of completion. Thus, no work is going on.

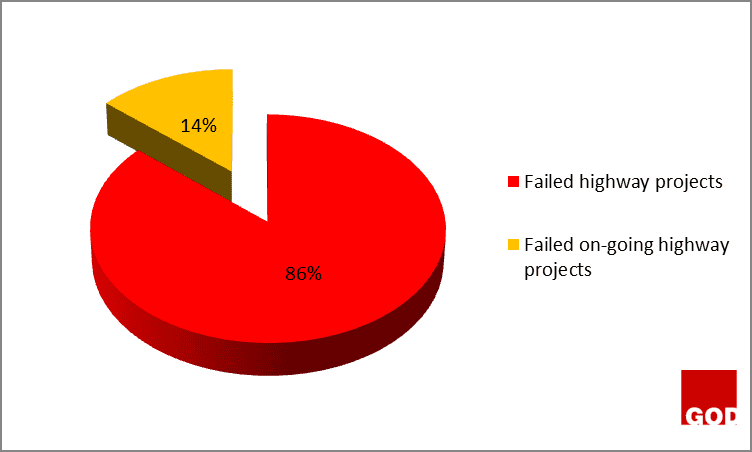

Figure 2 above showed that 14% of highway projects are still on-going projects because they have not exceeded the original date of completion as specified on the contract document. However, they are heading towards failure because they have been given an extended date of completion which can be as a result of some critical activities running behind schedule, causing delay on the critical path network of the projects. Moreover, the other 86% completely failed because they have exceeded their completion date specified on the contract document.

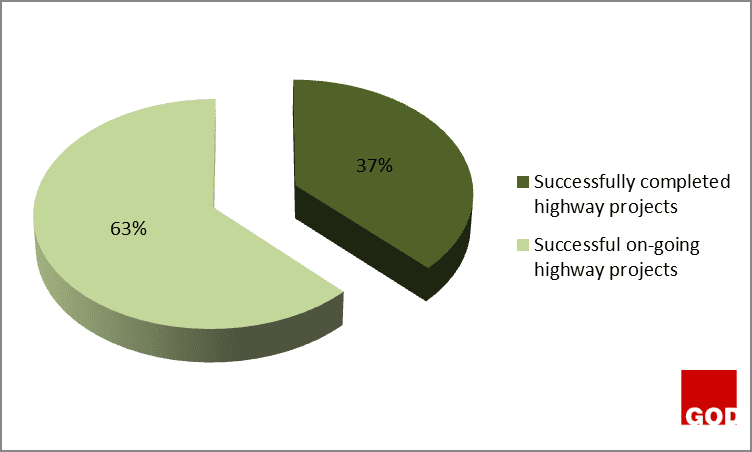

The figure 3 above showed that 63% of the successful highway projects are still on-going because they have not exceed their completion dates, and they are not yet completed. However, those on-going highway projects might end up as failed projects as a result of poor funding, discrepancy between the design and the construction on site, and conflict between the construction parties or stakeholders.

“Say what you will do, and do what you said” or “Say as you will do it, and do it as you said”

CONCLUSION AND RECOMMENDATION

The idea of knowing what a failed project is, the factors and the causes is very important in project management. Success in project management can neither be achieved nor measured without the knowledge of project failure, its factors, and causes in the Nigerian construction industries. This work has shown that project failure is as a result of exceeded time of delivery, cost overrun, and poor quality. However, the analysis was only done based on exceeded time of project delivery because of the nature of the data collected.

This work suggested a few approaches to help reduce the number of failed projects in the Nigerian construction industry if properly implemented. Firstly, Having good collaboration between the project stakeholders involved in a construction project at the early stage of project conception is most important in order to accomplish the project objectives, and deliver the project on time, within budget, and quality specified on the original contract document (Othman, 2006).

Secondly, Adopting the ISO 9000 technique which is used for quality management will also help in achieving a successful project delivery. This technique states “ say what you will do, and do what you said” or “say as you will do it, and do it as you said”. This technique is not an indication of high quality but it promotes control and consistency which leads to specialization, and improved productivity and quality. Also, adopting the principles of lean construction will help to reduce waste within the construction and stream-line activities in order to improve the on-time delivery of projects.

Thirdly, Learning from the precedent failed projects, how those projects failed, and the reason for their failures. This will help the project manager to plan and mitigate the risks of project failures in the future. And, finally, more seminars and workshops will help to educate and enlighten clients (the federal government representatives), users, contractors, engineers, and architects on what is project failure, the factors that contributes to abundant failed projects, and their causes.

REFERENCE

Abimbola, A. (Novermber 24, 2012). About 12,000 Federal Projects Abandoned across Nigeria. Premium times (November 16, 2015). Retrieved from www. Premium timesng.com/news/108450-about-12000-federal-projects-abandoned-across-nigeria.html.

Al-Khali, M.I and Al-Ghafly, M.A. (1999). Important Causes of Delays in Public Utility Projects in Saudi Arabia. Construction management and Economics, 17, 647-655

Aibinu, A.A and Jagboro, G.O. (2002). The Effects of Construction Delays on Project Delivery in Nigeria Construction Industry. International journal of Project management, 20(8), 593- 599.

Anigbogu, N. and Shwarka, M. (2011). Evaluation of Impact of the Public Procurement Reform Program on Combating Corruption Practices in Public Building Project Delivery in Nigeria. Environtech Journal, 1(2). 43-51.

Assaf, S. and Al-Hajji, S. (2006). Causes of Delays in large Construction Projects. International Journal of Project Management, 24, 349-357.

Atkinson , R. (1999). Project management: Cost, time, and quality, two best guesses and a Phenomenon, it’s time to accept other success criteria. International Journal of project Management, 17(6), 337-342.

Belout, A and Gauvrean, C. (2004). Factors Influencing the Project Success: The impact of human resource management. International Journal of project Management, 22, Pp. 1-11.

Butcher, N. and Demmers, L. (2003). Cost Estiumating Simplified. Retrieved from www.librisdesign.org.

Cookie-Davies, T. (2002). The Real Success Factors on Projects. International Journal of Project management, 20(3), 185-190.

Dim, N.U. and Ezeabasili, A.C.C (2015). Strategic Supply Chain Framework as an Effective Approach to Procurement of Public Construction Projects in Nigeria. International Journal of Management and Susutainability, 4(7), 163-172.

Hanachor, M. E. (2012). Community Development Projects Abandonment in Nigeria: Causes and Effects. Journal of Education and Practice, 3(6), 33-36.

Idrus, A., Sodangi, M., and Husin, M., H. (2011). Prioritizing project performance criteria within client perspective. Research Journal of Applied Science, Engineering and Technology, 3(10), 1142-1151.

Idrus, A. and Sodangi, M. (2010). Framework for evaluating quality performance of contractors in Nigeria. International Journal of Civil Environment and Engineering. 10(1), 34-39.

National Bureau of Statistics (January, 2015). Nigerian Construction Sector Summary Report: 2010-2012.

Kotangora, O. O. (1993). Project abandonment, Nigerian Tribune.

Osemenan, I. (1987). Project Abandonment. New Watch Magazine, Vol. 1, pp. 15.

Othman, M.,R. (2006). Forging main and sub-contractor relationship for successful projects. Retrieved from http://rakanl.jkr.gov.my/csfj/editor/files/file/projek/lessonslearned/MAIN&SUB_2.pdf

Phua, F.T.T and Rowlinson, S. (2003). Cultural Differences as an Explanatory Variable for Adversarial Attitude in the Construction Industry: The case of HongKong. Construction Management and Economics, 21, 777-785.

Reiss, B. (1993). Project Management Demystified. London: E and FN Spon Publishers.

Toor, S. R. and Ogunlana, S. O. (2008).Problems causing Delay in Major Construction Projects in Thailand. Construction management and Economics, 26, 395-408.

Toor, S. R. and Ogunlana, S. O. (2008). Critical COMs of Success in Large-Scale Construction Projects: Evidence from Thailand constructuction industry. International Journal of Project management, 26(4), 420-430.

Toor, S. R. and Ogunlana, S. O. (2009).Beyound the “Iron Triangle”: Stakeholder perception of key performance indicators (KPIs) for large-scale public sector development projects. International Journal of Project management, doi: 10.1016/j.ijproman.2009.05.005.

Toor, R. and Ogunlana, S. (2009). Construction Innovation: Information, process, management. 9(2), PP. 149-167.

Turner, J. R. (1993). The Handbook of project-Based Management: Improving the process for achieving strategic objective. London, McGraw-Hill.

Wright, J., N. (1997). Time and Budget: The twin imperatives of a project Sponsor. International Journal of Project Management, 15(3), 181-186.