Has Nigeria Become the World’s Junk Yard of Abandoned and Failed Mega Projects worth Billions?

Dim1, N. U., Okorocha2, K. A., & Okoduwa3 V. O.

The Nigerian construction industry is mostly concerned with the development and provision of projects such as roads, bridges, railways, residential and commercial real estates, and the maintenance necessary for the socio-economic developments contributes immensely to the Nigerian economic growth (Bureau of Statistics, 2015). Butcher and demmers (2003) described projects as an idea which begins and ends by filling a need. However, a project fails when its idea ends without meeting the needs and expectations of its stakeholders.

Nigeria Has Become the World’s Junk – Yard of Abandoned and Failed Projects worth Billions of Naira!

Hanachor (2013), revealed that projects form part of the basis for assessing a country’s development. However, a damming report from the Abandoned Projects Audit Commission which was set up by the Ex-President Goodluck Jonathan in 2011 revealed that 11,886 federal government projects were abandoned in the past 40 years across Nigerian (Abimbola, 2012). This confirmed the assertion by Osemenan (1987) “that Nigeria has become the world’s junk –yard of abandoned and failed projects worth billions of naira”.

Abandoned projects including building and other civil engineering infrastructure development projects now litter the whole of Nigeria.

Physical projects do not only provide the means of making life more meaningful for members of the community where the projects are located, successful projects also result in empowerment and collective action towards self improvement (Hanachor, 2013).

This Issue of Abandonment Has Been Left Without Adequate Attention for Too Long, and Is Now Having a Multiplier Effect on the Construction Industry in Particular and the Nigeria’s National Economy as a Whole. (Kotngora, 1993)

PROJECT FAILURE

Project Failure might mean a different thing to different stakeholders. A project that seemed successful to one stakeholder may be a total failure to another (Toor and Ogunlana, 2008). Some stakeholders, more especially the project users and some private owners, think of failed projects as a situation where a completed building project collapsed, a situation where by a completed dam project stopped working after few days of completion, or a completed road project that broke down after few months of completion. Other experienced stakeholders, such as engineers and architects conform to the iron triangle by Atkinson (1999) which states that the most strategically important measures of project failure are “time overrun”, “cost overrun”, and “poor quality”.

Turner (1993) noted that a project fails when the project specifications are not delivered within budget and on time; the project fails to achieve its stated business purpose; the project did not meet the pre-stated objectives; the project fails to satisfy the needs of the project team and supporters; and the project fails to satisfy the need of the users and other stakeholders. Lim and Mohamed (1999) cited in Toor and Ogunlana (2009) clarified that there are two possible view points to project failure namely; the macro-level and the micro-level. They further explained that the macro view point reviews if the original objectives and concepts of the project was met. Usually the end users and the project beneficiaries are the ones looking at the project failure from the macro view point, where as the project design team, the consultants, contractors, and suppliers review projects from a micro view point focusing on time of delivery, budget, and poor quality.

In the early 1990s, the failure as well as the success of any project was determined by the project duration, monetary cost, and the performance of the project (Idrus, Sodangi, and Husin, 2011). Belout and Gauvrean (2004), also confirmed that the project management triangle based on schedule, cost, and technical performance is the most useful in determining the failure of a project. Moreover, a project is considered as an achievement of specific objectives, which involves series of activities and tasks which consume resources, are completed within specifications, and have a definite start and end time (Muns and Bjeirmi 1996, cited in Toor and Ogunlana, 2009). Reiss (1993) in his suggestion stated that a project is a human activity that achieves a clear objective against a time scale. Wright (1997) taking the view of clients, suggested that time and budget are the only two important parameters of a project which determines if a project is successful or failed. Nevertheless, many other writers such as Turner, Morris and Hough, wateridge, dewit, McCoy, Pinto and Slevin, saarinen and Ballantine all cited in Atkinson (1999), agreed that cost, time, and quality are all success as well as failure criteria of a project, and are not to be used exclusively.

FACTORS OF PROJECT FAILURE

Cookie-Davies (2002) stated the difference between the success criteria and the failure factors. He stated that failure factors are those which contributed towards the failure of a project while success criteria are the measures by which the failure of a project will be judged. The factors constituting the failure criteria are commonly referred to as the key performance indicators (KPIs).

Time and Cost Overrun

The time factor of project failure cannot be discussed without mentioning cost. This is because the time spent on construction projects has a cost attached to it. Al-Khali and Al-Ghafly, (1999); Aibinu and Jagboro, (2002) confirmed that time overrun in construction projects do not only result in cost overrun and poor quality but also result in greater disputes, abandonment and protracted litigation by the project parties. Therefore, focus on reducing the Time overrun helps to reduce resource spent on heavy litigation processes in the construction industry (Phua and Rowlinson, 2003). Most times, the time overrun of a project does not allow resultant system and benefits of the project to be taking into consideration (Atkinson, 1999). Once a project exceeds the contract time, it does not matter anymore if the project was finally abandoned or completed at the same cost and quality specified on the original contract document, the project has failed. Furthermore, Assaf and Al-Hejji, (2006) noted that time overrun means loss of owner’s revenue due to unavailability of the commercial facilities on time, and contractors may also suffers from higher over heads, material and labour costs.

Poor quality/Technical Performance

The word “Performance” has a different meaning which depends on the context it is being used and it can also be referred to as quality. Performance can be generally defined as effectiveness (doing the right thing), and efficiency (doing it right) (Idrus and Sodangi, 2010). Based on this definition of performance, at the project level, it simply means that a completed project meets fulfilled the stakeholder requirements in the business case.

CAUSES OF PROJECT FAILURE

A lot of research studies have investigated the reasons for project failures, and why projects continue to be described as failing despite improved management. Odeh and Baltaineh, 2002; Arain and Law, 2003; Abdul-Rahman et al., 2006; Sambasivan and Soon, 2007; all cited in Toor and Ogunlana, 2008, pointed out the major causes of project failures as Inadequate procurement method; poor funding and availability of resources; descripancies between design and construction; lack of project management practices; and communication lapses

The contract/procurement method

A result obtained from two construction projects which were done by the same contractor but using different procurement methods showed that rework, on the design part which occurs when the activities and materials order are different from those specified on the original contract document, makes it difficult for the project to finish on the expected time (Idrus, Sodangi, and Husin, 2011). This is as a result of non-collaboration and integration between the design team, contractor, and tier suppliers. The rework on the design portion has a huge impact on project failure leading to the time overrun. The traditional method of procurement has inadequate flexibility required to facilitate late changes to the project design once the design phase of the construction project has been concluded.

Nigerian most widely used procurement method is the traditional method of procurement (design-bid-construct) which has been confirmed to be less effective to successfully delivery of a construction project (Dim and Ezeabasili, 2015). And, the world bank country procurement assessment report (2000) cited in Anigbogu and Shwarka, (2011) reported that about 50% of projects in Nigeria are dead even before they commence because they were designed to fail.

The way the construction projects are contracted, in addition to the way the contracts are delivered, contributes to the causes of projects failure. Particularly, among the methods of project contracting is lump-sum or a fixed-price contracting method, in which the contractor agrees to deliver a construction project at a fixed price. The fixed-price contract can be low-bid or not however, once the contract cost has been agreed upon the contract award, it cannot be changed. And, contractors are expected to honor and deliver the contract agreement, failure to do so can result in a breach of contract which can result in the contractor being prosecuted.

Awarding a contract to an unqualified personnel also contributes to project failures. When a contractor places more emphasis on money and the mobilization fee after a construction project has been initiated instead of getting the right workforce and skilled professionals that will execute the project. Instead the workforce chosen will often not be base on competence and required skills rather it will be based on availability. Moreover, poor strategy and planning by contractors who have overloaded with work also contributed to one of the causes of project failure.

Poor funding/Budget Planning

A lot of public projects in the Nigerian construction industry failed as a result inadequate funding, and the difference between the national annual budget and the budget actual released. Most of the Nigerian public projects are signed even before the actual release of the national budget. The difference in budget of the contracted project and the actual budget release can get the contracted company stuck as a result of inflation of prices, scarcity of construction material at the time of the budget release and mobilization to site. Also un-planned scope of work which can be as a result of the contractor working on another contract when he is called back to mobilization to start work. Moreover, poor budget planning is a regular mistake made by some contractors by not undertaking feasibility assessments before starting the design. The construction project should be planned according to the available resources and not according to the unrealistic expectations a client has in mind.

Discrepancies Between the Design and Construction

Limited collaboration between the contractors, engineers, and the architect results in discrepancies between the project designs and construction on site, and further leads to rework. Changes on a project designs, and changing to the scope of work in the middle of construction processes on site can be dangerous, and can lead to time overrun, increase in cost, and most of all can lead to abandonment. Moreover, many cases have been seen where the designs from the architects are not buildable on site, while In some cases, most contractors are unable to adequately specify the scope of work for the construction processes on site. Therefore any default on the design by the architect can be an opportunity for the contractor to make more money which might cause the project duration to exceed the time specified on the contract document.

RESEARCH METHODOLOGY

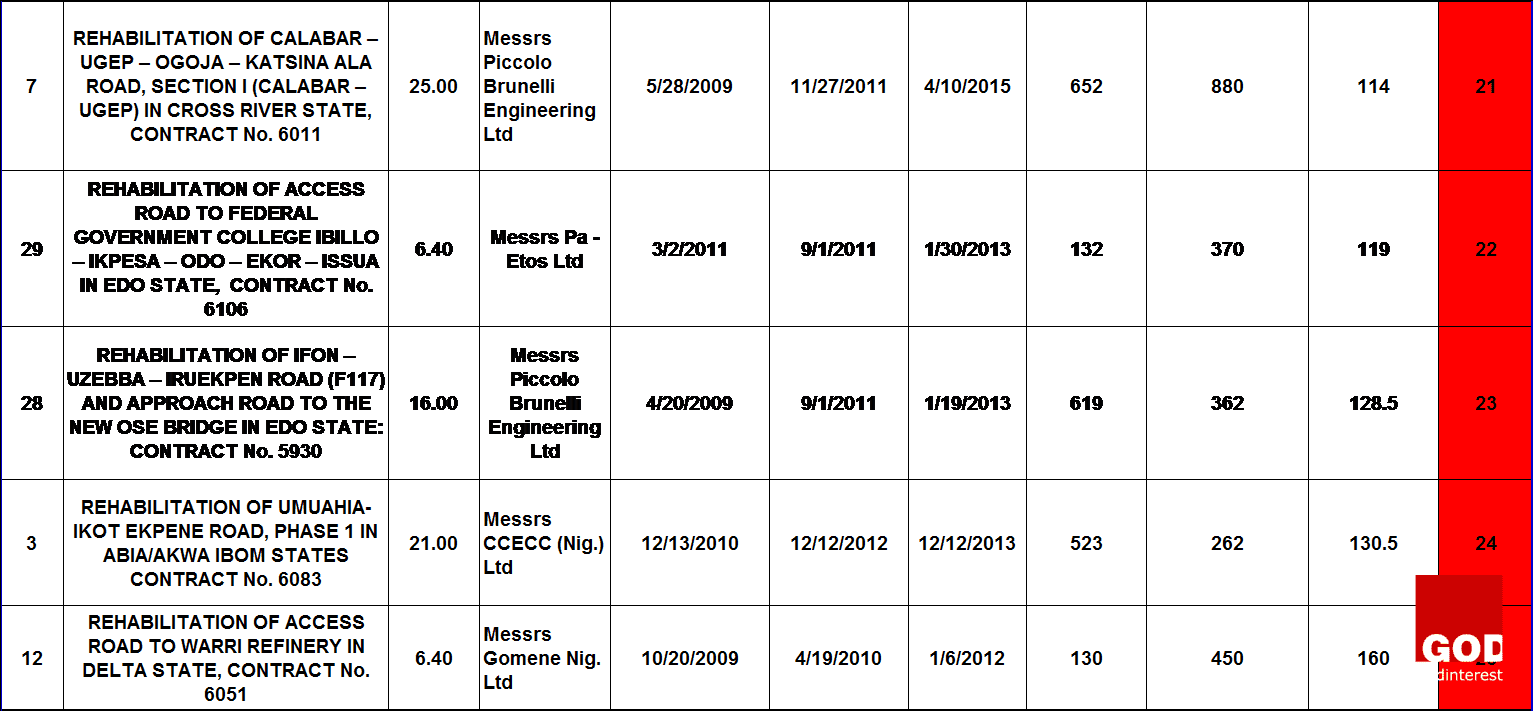

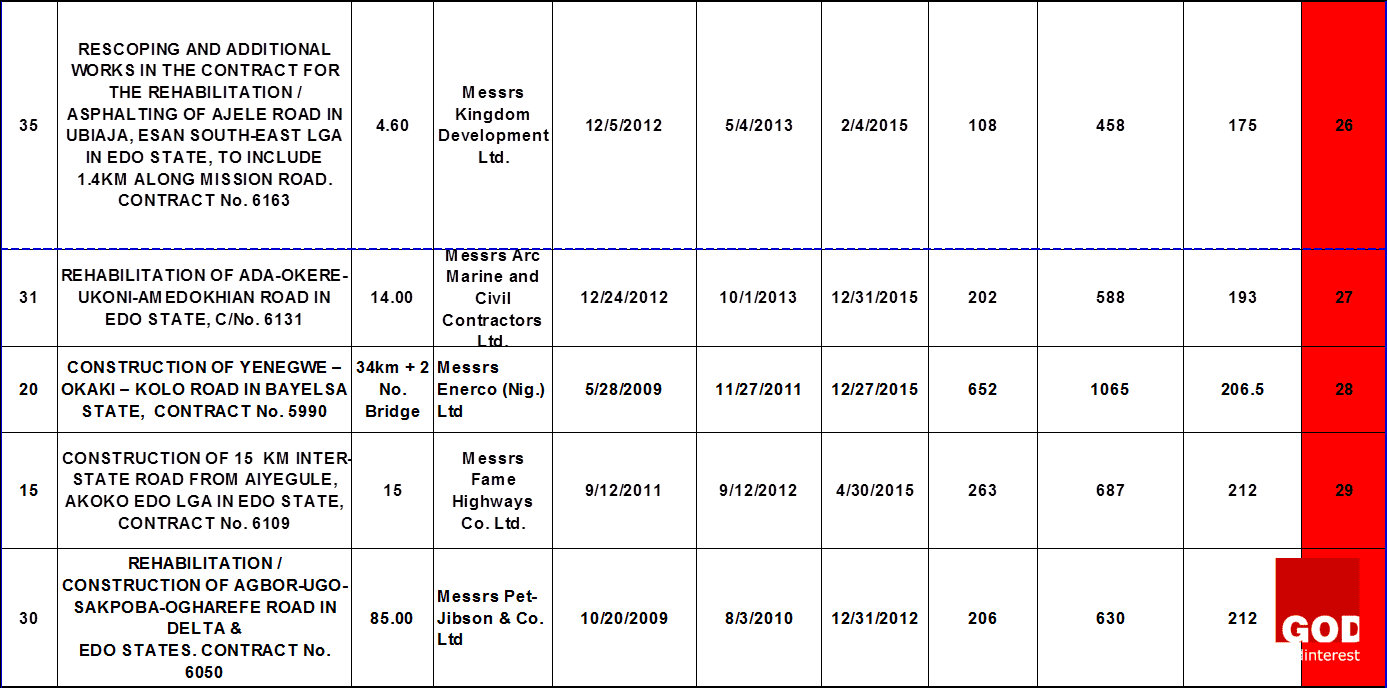

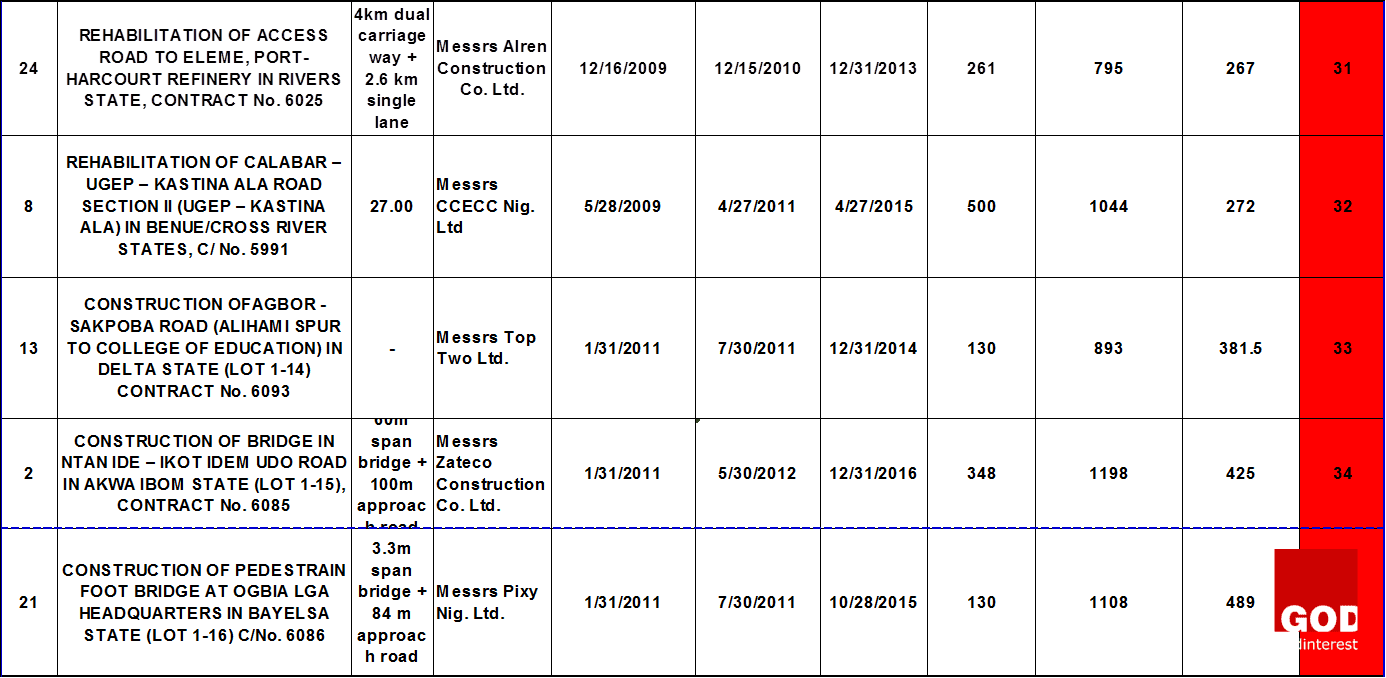

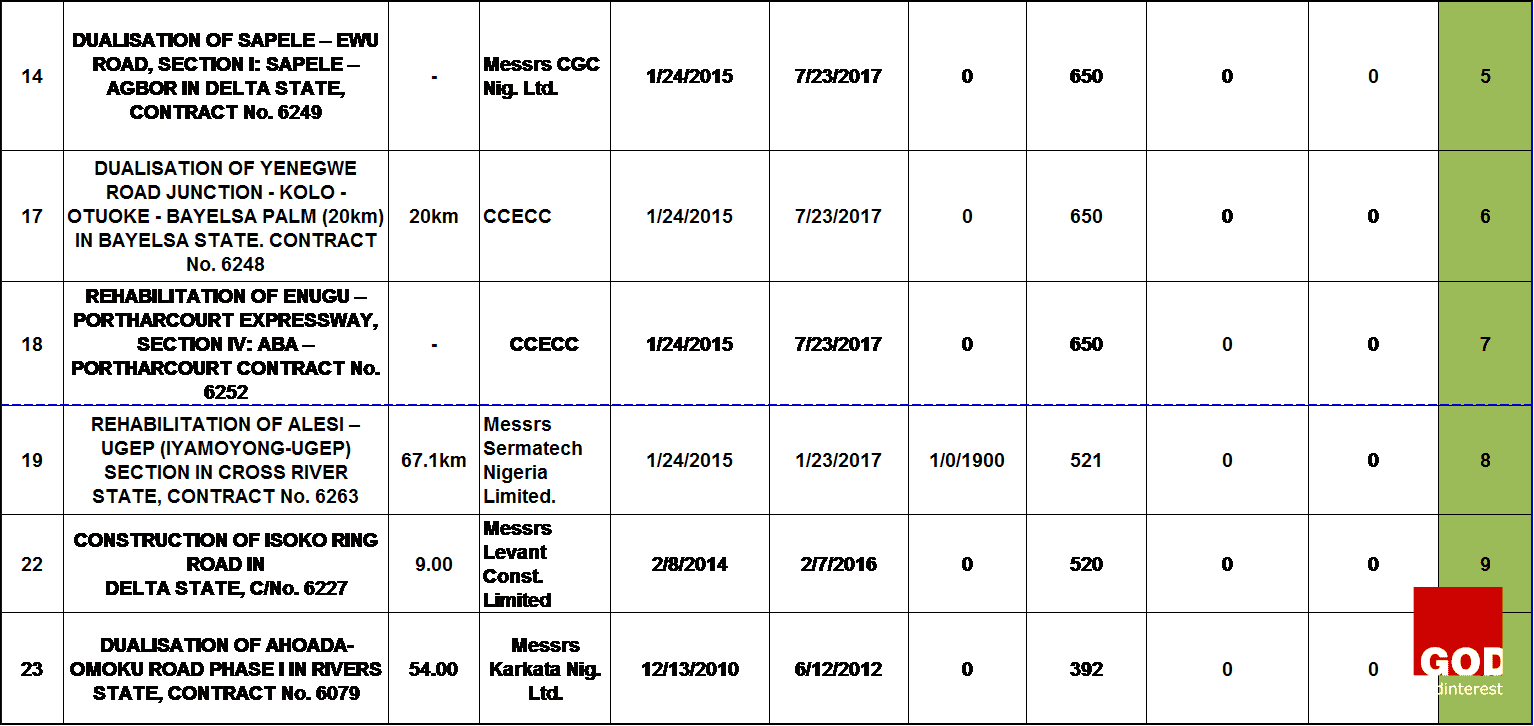

This research starts with a general reasoning or theory which says that the major cases of project failure in the Nigerian construction industry are defined based on time overrun and cost overrun. The findings from the data analysis will help on the decision to accept the theory or not. The research data was collected from the progress report for the month ending of October, 2015 published by the Nigeria of Federal Ministry of works on thirty-nine on-going highway construction projects at the South-South geopolitical zone. The table 1 below shows the information on the data collected which comprises of the project title, contract Number, project description, the contractor that was awarded the projects, the date of project commencement, date of completion and the extended date if any. The scheduled time for each project was specified as follows: project commencement date labeled as “a”, project completion date labeled as “b”, and the extended date labeled as “c”.

DATA ANALYSIS

The data analysis was done with the use of Microsoft excel. The analysis started by obtaining the number of days between the date of commencement of each project and the date of completion to show the duration of each highway project. And, the number of days between the project completion date and the extension date showed the time-overrun. The project duration and the extended days were obtained with the use of NETWORKDAYS function in Microsoft Excel which calculates the number of working days between two dates excluding weekends and any dates identified as holidays.

The standard deviation between the specified project duration for each highway projects and the extended days was calculated to obtain the extent to which each highway project contract failed on its time of delivery. This was denoted as the degree of failure. The table 1 above showed the projects ranking which was done based on the degree of failure of all the highway projects. The highway projects that were ranked from one to sixteen have low degree of failure and are represented with green color, while the rest are those with high degree of failure and are represented with red color.

FINDINGS

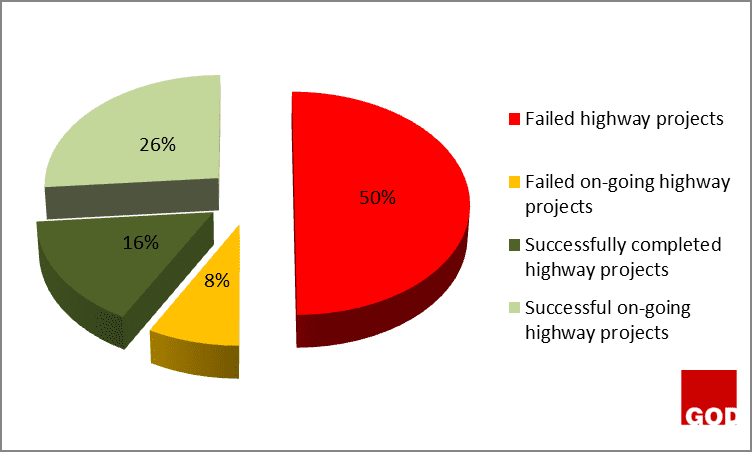

The findings made showed that the successfully completed highway projects have no extended days or time overrun, and the successful on-going highway projects are still on schedule and have no extended days unlike the on-going highway projects that have already failed as a result of the extended dates. Other projects have been abandoned because they have exceeded the delivery date as specified on the contract document, and have no extended date of completion. Thus, no work is going on.

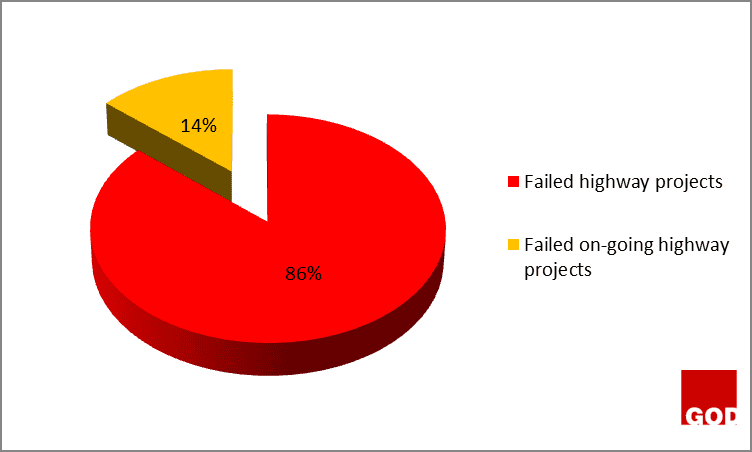

Figure 2 above showed that 14% of highway projects are still on-going projects because they have not exceeded the original date of completion as specified on the contract document. However, they are heading towards failure because they have been given an extended date of completion which can be as a result of some critical activities running behind schedule, causing delay on the critical path network of the projects. Moreover, the other 86% completely failed because they have exceeded their completion date specified on the contract document.

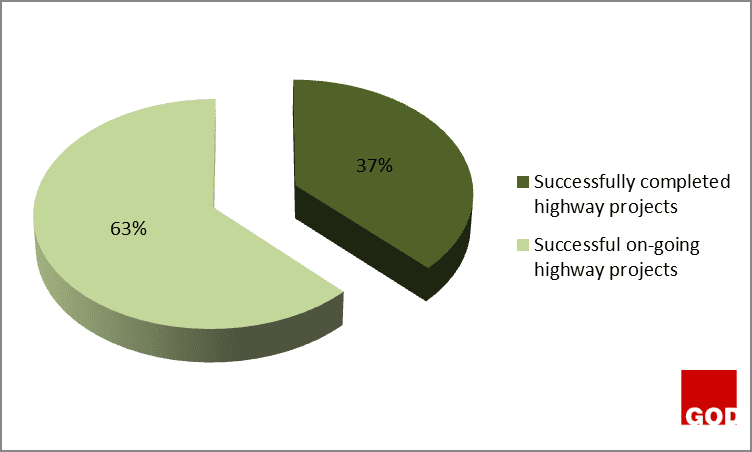

The figure 3 above showed that 63% of the successful highway projects are still on-going because they have not exceed their completion dates, and they are not yet completed. However, those on-going highway projects might end up as failed projects as a result of poor funding, discrepancy between the design and the construction on site, and conflict between the construction parties or stakeholders.

“Say what you will do, and do what you said” or “Say as you will do it, and do it as you said”

CONCLUSION AND RECOMMENDATION

The idea of knowing what a failed project is, the factors and the causes is very important in project management. Success in project management can neither be achieved nor measured without the knowledge of project failure, its factors, and causes in the Nigerian construction industries. This work has shown that project failure is as a result of exceeded time of delivery, cost overrun, and poor quality. However, the analysis was only done based on exceeded time of project delivery because of the nature of the data collected.

This work suggested a few approaches to help reduce the number of failed projects in the Nigerian construction industry if properly implemented. Firstly, Having good collaboration between the project stakeholders involved in a construction project at the early stage of project conception is most important in order to accomplish the project objectives, and deliver the project on time, within budget, and quality specified on the original contract document (Othman, 2006).

Secondly, Adopting the ISO 9000 technique which is used for quality management will also help in achieving a successful project delivery. This technique states “ say what you will do, and do what you said” or “say as you will do it, and do it as you said”. This technique is not an indication of high quality but it promotes control and consistency which leads to specialization, and improved productivity and quality. Also, adopting the principles of lean construction will help to reduce waste within the construction and stream-line activities in order to improve the on-time delivery of projects.

Thirdly, Learning from the precedent failed projects, how those projects failed, and the reason for their failures. This will help the project manager to plan and mitigate the risks of project failures in the future. And, finally, more seminars and workshops will help to educate and enlighten clients (the federal government representatives), users, contractors, engineers, and architects on what is project failure, the factors that contributes to abundant failed projects, and their causes.

REFERENCE

Abimbola, A. (Novermber 24, 2012). About 12,000 Federal Projects Abandoned across Nigeria. Premium times (November 16, 2015). Retrieved from www. Premium timesng.com/news/108450-about-12000-federal-projects-abandoned-across-nigeria.html.

Al-Khali, M.I and Al-Ghafly, M.A. (1999). Important Causes of Delays in Public Utility Projects in Saudi Arabia. Construction management and Economics, 17, 647-655

Aibinu, A.A and Jagboro, G.O. (2002). The Effects of Construction Delays on Project Delivery in Nigeria Construction Industry. International journal of Project management, 20(8), 593- 599.

Anigbogu, N. and Shwarka, M. (2011). Evaluation of Impact of the Public Procurement Reform Program on Combating Corruption Practices in Public Building Project Delivery in Nigeria. Environtech Journal, 1(2). 43-51.

Assaf, S. and Al-Hajji, S. (2006). Causes of Delays in large Construction Projects. International Journal of Project Management, 24, 349-357.

Atkinson , R. (1999). Project management: Cost, time, and quality, two best guesses and a Phenomenon, it’s time to accept other success criteria. International Journal of project Management, 17(6), 337-342.

Belout, A and Gauvrean, C. (2004). Factors Influencing the Project Success: The impact of human resource management. International Journal of project Management, 22, Pp. 1-11.

Butcher, N. and Demmers, L. (2003). Cost Estiumating Simplified. Retrieved from www.librisdesign.org.

Cookie-Davies, T. (2002). The Real Success Factors on Projects. International Journal of Project management, 20(3), 185-190.

Dim, N.U. and Ezeabasili, A.C.C (2015). Strategic Supply Chain Framework as an Effective Approach to Procurement of Public Construction Projects in Nigeria. International Journal of Management and Susutainability, 4(7), 163-172.

Hanachor, M. E. (2012). Community Development Projects Abandonment in Nigeria: Causes and Effects. Journal of Education and Practice, 3(6), 33-36.

Idrus, A., Sodangi, M., and Husin, M., H. (2011). Prioritizing project performance criteria within client perspective. Research Journal of Applied Science, Engineering and Technology, 3(10), 1142-1151.

Idrus, A. and Sodangi, M. (2010). Framework for evaluating quality performance of contractors in Nigeria. International Journal of Civil Environment and Engineering. 10(1), 34-39.

National Bureau of Statistics (January, 2015). Nigerian Construction Sector Summary Report: 2010-2012.

Kotangora, O. O. (1993). Project abandonment, Nigerian Tribune.

Osemenan, I. (1987). Project Abandonment. New Watch Magazine, Vol. 1, pp. 15.

Othman, M.,R. (2006). Forging main and sub-contractor relationship for successful projects. Retrieved from http://rakanl.jkr.gov.my/csfj/editor/files/file/projek/lessonslearned/MAIN&SUB_2.pdf

Phua, F.T.T and Rowlinson, S. (2003). Cultural Differences as an Explanatory Variable for Adversarial Attitude in the Construction Industry: The case of HongKong. Construction Management and Economics, 21, 777-785.

Reiss, B. (1993). Project Management Demystified. London: E and FN Spon Publishers.

Toor, S. R. and Ogunlana, S. O. (2008).Problems causing Delay in Major Construction Projects in Thailand. Construction management and Economics, 26, 395-408.

Toor, S. R. and Ogunlana, S. O. (2008). Critical COMs of Success in Large-Scale Construction Projects: Evidence from Thailand constructuction industry. International Journal of Project management, 26(4), 420-430.

Toor, S. R. and Ogunlana, S. O. (2009).Beyound the “Iron Triangle”: Stakeholder perception of key performance indicators (KPIs) for large-scale public sector development projects. International Journal of Project management, doi: 10.1016/j.ijproman.2009.05.005.

Toor, R. and Ogunlana, S. (2009). Construction Innovation: Information, process, management. 9(2), PP. 149-167.

Turner, J. R. (1993). The Handbook of project-Based Management: Improving the process for achieving strategic objective. London, McGraw-Hill.

Wright, J., N. (1997). Time and Budget: The twin imperatives of a project Sponsor. International Journal of Project Management, 15(3), 181-186.

Small Projects Often Mean Greater Innovation

Small projects often embody more innovation than larger more costly or high profile ones.

Innovation is a wide concept that includes improvements in processes, products and services. It involves incorporating new ideas which generate changes that help solve the needs of a company and so increase its competitiveness. That’s hardly big news. But what may be surprising to some is that innovation has itself, well, innovated and it isn’t what it used to be.

New materials and energy, design approaches, as well as advances in digital technology and big data, are creating a wave of innovation within the construction industry. These new ideas are increasingly often tested and proven on smaller and agiler projects. Investing time and money is well spent on these ideas and technical improvements can then be used on large-scale developments.

Here are three exciting small projects:

Milan, Italy

1. Vanke Pavilion – Milan Expo 2015

The corporate pavilion for Vanke China explores key issues related to the theme of the Expo Milano 2015, “Feeding the Planet, Energy for Life”.

Situated on the southeast edge of the Lake Arena, the 800-square meter pavilion appears to rise from the east, forming a dynamic, vertical landscape.

The original tiling pattern would have resulted in thousands of ceramic tiles of different sizes and shapes. The resulting complexity and lack of repetition could have led to high costs and a longer erection time.

Working with Architects Studio Libeskind, Format Engineers (Engineering Designers with backgrounds in structural engineering, coding, mathematics, and architecture) changed the pattern from thousands of different tiles to less than a dozen and simplified the backing structure generating huge cost savings. Format Engineers also proposed ‘slicing’ of the building and then fabrication of the primary structure of steel ribs using low tech flat steel plate elements. These were then used in a series of long span portalised frames reminiscent of the ribs and spars in traditional boat building resulting in a column-free area for the display of Chinese Cultural Heritage.

The frame was built to a budget and without difficulty ahead of the neighboring Expo buildings.

Building Size

12 meters high

740 mq gross floor area (exhibition, service & VIP levels)

130 mq roof terrace

Architect: Studio Libeskind

Engineer: Format Engineers

2. Oxford Brookes Rain Pavilion

The Rain Pavilion is an urban forest sculpture forming the front entrance to Oxford Brookes University’s Architecture Faculty.

“Rain Pavilion artwork is a sensory experience for the community.”

The complex form required extensive wind modeling and comprehensive structural analysis within a generative 3d model. This was allied with Format Engineers in-house code for the self-organization of voids and their subsequent redistribution.

.At each stage of the design process different modeling and analysis techniques were used to exploit the form and to optimise the structure. The considerable challenges posed by the slenderness of the structure and its dynamic behavior under wind were resolved by combining Computational Fluid Dynamics (CFD) (a branch of fluid mechanics that uses numerical analysis and algorithms to solve and analyze problems that involve fluid flows) with a generative design environment. Conceptual design introduced the ideas of tubular stems and folded steel canopies, both of which were perforated by circular holes arranged to allow the interplay of light and water through the structure. The voids were generated using a self-organizing process.

Grasshopper (a graphical algorithm computer 3-D modeling tool) was used to produce a mesh that could include the voids in both the stems and the petals.

The Rain Pavilion is designed to celebrate the sound of rain, and the noise of water interacting with different sections of the installation is part of the experience of passing through it. The structure has a design life of five years and can be transported to other locations.

Architect: Oxford Brookes University, Oxford, UK

Engineer: Format Engineers

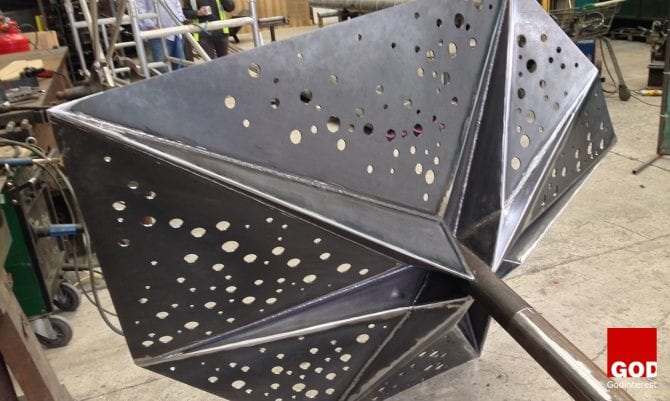

3. KREOD Pavilion

The KREOD pavilions were first erected on the London Greenwich Olympic site in 2012. Easily rearranged, three pod-like pavilions were formed with a wooden structural framework comprised of an open hexagonal composition.

Standing three meters tall, each double-curved wooden shell enclosed a footprint of 20 square meters, totaling 60 square meters. A waterproof tensile membrane sealed the interior from the elements fully portable with demountable joints, the individual components can be stacked for efficient transportation.

Chun Qing Li the architect required a temporary exhibition or function space that could be erected and demounted mostly by hand and by untrained staff. The quality of finish needed to echo that of handmade furniture and had to be low cost and quick to erect. The continuously changing double curved form of the enclosure meant that in theory, every nodal connection was different. A conventional bolted solution would have cost hundreds of pounds per fixing. Format Engineers suggestion of a ‘reciprocal’ jointed timber grid shell required standard bolts which equated to a fraction of the normal cost. It also allowed the structure to be built from simple and light flat timber elements.

The structure used Kebony timber throughout, a sustainable alternative to tropical hardwood. As this material had not previously been used in a structural context Format Engineers undertook load testing of the material and the connections at the University of Cambridge. The timber was fabricated using CNC routing (a computer controlled cutting machine) allowing a highly accurate fit between members and basic erection on site.

Architect: Chun Qing Li

Engineer: Format Engineers

5 of the World’s Most Spectacular Megaprojects

We seem to be entering a new age of megaprojects as countries around the world mobilise the private sector to invest heavily in multi-billion or sometimes multi-trillion dollar infrastructure initiatives.

Megaprojects (sometimes also spelled “mega projects”) are very large investment projects and require care in the project development process to reduce any possible optimism bias and strategic misrepresentation.

The most expensive large-scale megaprojects in the world range from bridges, tunnels, highways, railways, airports, seaports, power plants, dams and wastewater projects to entire city districts.

Megaprojects seem to be practically recession-proof and have continued despite the 2008 global economic slowdown likely spurred megaproject construction, since the governments of some countries among them China, India, and the United States saw investment in infrastructure as a way to stimulate growth. Moreover, many large corporations are locked into megaprojects, because only enormous undertakings seem capable of nudging their bottom lines.

Here, we take a look at 5 of the biggest, most important and spectacular megaprojects around the world.

Songjiang Hotel, China

Three Gorges Dam

Man has long used technology to harness nature and dam building has always been one of the most controversial methods.

Building a dam causes dramatic effects on the environment, yet can benefit man in innumerable ways.

Three Gorges Dam located in Sandouping, Yiling, Hubeiis is the largest power station in the world and took 14 years to complete at a cost of USD $37 billion ( ¥180 billion). The original estimated cost was USD $6 billion ( ¥20 billion). It can produce as much as 15 nuclear power plants and is expected to create 10% of China’s entire energy supply.

The Three Gorges Dam has moved 39 trillion kilograms of water 175 metres above sea level which scientists believe has altered the planet enough to change the speed at which the earth rotates.

The dam was first suggested by Sun Yat-sen, the first president of the Republic of China in 1919 and people have been working on it, researching how it would work and where exactly it would go for nearly 100 years.

London Crossrail

Crossrail is Europe’s largest infrastructure project and is set to boost London’s rail capacity by 10%. The project will deliver approximately 11.9km of twin bore tunnels.

The $23 billion development 73-mile rail project will connect London from East to West, improving access to Heathrow Airport, central London as well as city’s surrounding towns and suburbs.

Eight boring machines have been cutting their way through earth to create 26 miles (42km) of tunnels.

Construction of Crossrail began at Canary Wharf in London Docklands on 15 May 2009, with tunnelling work starting in May 2012.

The Crossrail project is about 65% complete and engineers will now continue upgrading existing stations and building new stations in central London and London Docklands.

Beijing International Airport Terminal 1 to be World’s Biggest

Beijing’s new international airport

January 2013 saw work approved for a new airport in Beijing. With large sweeping, non-conforming arches that span inwards with curves to the interior, there is a definite stamp of Zaha Hadid Architects with their design language.

Playing host to eight runways and with the capabilities to cater for 130 million passengers every year, Beijing’s new international airport will be among the world’s largest and busiest once complete in 2017.

One Giant Leap for Mankind

International Space station

The International Space Station (ISS) is the largest artificial body in orbit and can often be seen with the naked eye from Earth.

It may be one of the most ambitious scientific ventures ever and also the largest masterpiece of the human engineering in orbit around Earth at present. The station consists mainly of habitable and science modules, external trusses and solar panels to provide power.

The ISS provides a platform to conduct scientific research including astrobiology, astronomy, human research including space medicine and life sciences, physical sciences, materials science, space weather and weather on Earth.

What exciting projects did we miss on our list? Let us know in the comments section below.

13 Basic Facts You Should Know about Modular Homes

Modular homes sometimes referred to as “factory-built construction“, encompass a category of housing built in sections typically at a factory location. These houses must conform to local and regional building codes for the country the buyer plans to situate the dwelling.

Just like site-built housing, construction teams build modular homes to last and increase in value over time. As the factory finishes building sections of the house, each piece is transported to the homeowners build site on large truck beds. Local building contractors then assemble the house and inspectors ensure the manufacturer has built your residence to code. Most customers find that modular housing is less expensive than site-built homes.

1. Benefits of Construction

One of the benefits of construction is that manufacturers build them indoors in an enclosed factory setting, where the materials used to build the homes are not subject to adverse weather during construction.

Most building contractors can finish erecting a house in as little as 1-2 weeks, though it may take up to 4 weeks or more for local contractors to finish building the dwelling on-site once it has been delivered.

2. Differences Between Modular and Site Built

Modular homes are not the same as site-built homes, which contractors create 100% at the build site. That means the

contractor must collect all the materials for a house and built it on-site. Like a modular home, the site-built home must conform to all regional, state and local building codes. Many refer to site-built construction as stick-built homes. Stick built housing is also well-built and designed to last a lifetime.

3. Difference Between Modular and Manufactured

Manufactured housing is another form of factory construction. Many consumers have mistakenly referred to these homes in the past as mobile homes. Others refer to manufactured homes as trailers. Manufacturers do build these houses in a factory like modular homes on a steel chassis.

The manufacturer then transports sections of the home to the building site as completed. These dwellings are usually less expensive than both modular housing and site built housing, in part because they don’t come with a permanent foundation. Trailers and mobile homes are more likely to depreciate than modular or site built homes.

4, Advantages of Modular Construction Over Site Built

Modular homes offer many advantages over traditional site built dwellings. Many consider modular homes a hybrid breed of housing. Not a manufactured house and not a site built house, these homes offer consumers multiple benefits including costs savings, quality and convenience. In many ways modular homes surpasses site built housing in quality and efficiency.

Modulars have grown up. They are more and more becoming a mainstream selection for first time and secondary homebuyers. Most people now realise they don’t’ have to give up design quality or customization to buy a prefabricated house. One of the biggest misconceptions people have of prefabricated housing is they are look alike. “Boxy” is not a word that can begin to describe prefab dwellings. In fact, more suitable descriptions of these buidlings would include: “Elegant, durable, customised and high-class”. Many people find they can afford to include more specialization and customization when they buy a factory built house over a traditional stick built construction.

5. Cutting-edge Designs

Looking for a building design with a little pizzazz? You need to check out the latest architectural designs associated with prefabricated buildings. Firms are now building more elegant and unique designs to meet the increasing demands of selective customers. People are selecting modular designs over stick built designs to build their dream homes.

6. Customised Design and Modification

There are hundreds of companies that offer modular prefabricated construction kits and plans, and most employ various architects and specialized designers to help customize your home. That means you have more choices and a wider selection of designers to choose from. If you don’t find a style you like with one designer you can often move onto another, without even switching manufacturers.

7. Huge Range of Selection

Its always best to select a home that matches your lifestyle and design preferences.

8. Rapid Customisation

These are often the ideal selection for homeowners in need of a speedily designed homes. You simply can’t build a dwelling faster. Site built housing can take months to design and build. A manufacturer can design and place a prefab house in a few short weeks. You can pick from just as many different styles as you would a site built home if not more, but don’t have to wait weeks for contractors to build your custom house.

9. Precise Budgeting and Timing

Yet another benefit of these designs is the lack of guesswork involved. You don’t have to worry about how something will look. You know that everything will arrive to the build site complete and you will know the exact outcome. You also don’t need to worry about unexpected expenses, which is commonly the case with site built homes. With a prefabricated house, you know exactly what your home will cost and can control that cost from the point of buying to final construction. This isn’t the case with stick built housing. With stick built housing you also have to worry about surprises in the middle of construction. It isn’t uncommon for example, for a contractor to quit in the middle of a project. If this happens you have few choices.

Your home will sit partially built until you are able to find a new construction team. This alone may cost you valuable time and money.

10. Improved Energy Efficiency

Many prefab houses also come with what manufacturers call the “Energy Star” certification. This is a national company that promotes energy efficiency. Buildings with this label use 30-40 percent less energy yearly than traditional stick built housing.

This saves you time and money. Some key features of prefabricated housing that help improve energy efficiency include tight installation, high performance and weather resistant windows, controlled air systems and duct systems, upgraded air-conditioning and heating units and use of efficient lighting and heating appliances. As a bonus, these features not only save on annual energy costs but also improve the quality of your indoor air. Think energy efficiency isn’t significant? Think again. Over the lifetime of your house you could save thousands of pounds in energy bills by buying a prefabricated dwelling.

11. Design Modification is Easier

Most prefab homemakers now use computer aided design systems when conducting operations. This adds to the efficiency of construction and improves the appearance and architecture of homes. Prefabricated construction ranges from plain vanilla styling to intricate and complex modern designs.

12. On Time and on Budget

Perhaps the two biggest features or benefits of prefabricated housing that manufacturers hone in on are the speed that they can be built with and the competitive pricing they can offer on the final product. This is one reason that modular homes are gaining popularity.

13. Appreciate in Value

These dwellings also appreciate much like site built housing designs. Most homeowners are interested in building value in their house over time. Prefab housing afford you the opportunity to do this (keep in mind however much appreciation is dependent on real estate location). Select a good build site and your house will gain significant value over time. Other factors may also affect appreciation including landscaping and how well the house is cared for year after year. These factors also affect site built housing. Unlike mobile homes, which depreciate, a modular homeowner can expect to gain value from their home year after year. Study after study suggests that modular homes appreciate just as well as site built homes. They are also just as easily insured and financed.

As far as risk goes, you are no more at risk buying prefabricated housing than site built construction.

Modular Home Facts

- Modular homes appraise the same as their on-site built counterparts do.

- Modular homes can be more easilly customised.

- Most modular home companies have their own in-house engineering departments that utilize CAD (Computer Aided Design).

- Modular home designs vary in style and size.

- Modular homes are permanent structures – “real property.”

- Modular homes are considered a form of “Green Building.”

- Modular homes are faster to build than a 100% site-built home.

- Home loans for modular are the same as if buying a 100% site-built home.

- Insuring your modular home is the same as a 100% site-built home.

- Modular homes can be built to withstand 175 mph winds.

- Modular homes can be built for accessible living and designed for future conveniences.

Would you consider a modular home for yourself, or are you more of a traditionalist?

Pocket Living in London: Micro-flats Gain Favour as the Answer to Big City Urban Density

Young Londoners have revealed that they would rather rent a tiny studio flat than a large property in a less desirable area.

We Haven’t Reached the Density of Hong Kong. But We’re Heading That Way

London’s population is expected to reach 10m by 2031 from its current 8.3m. London needs an estimated 49,000 new homes a year. This is not a new phenomenon, architects have confronted population growth and social changes before.

Obvious solutions include rental and shared ownership, while community building is also gaining ground in the UK. But there are other solutions out there, adding to the bigger picture. One of these is Pocket Living micro-flats, backed by Mayor Boris Johnson.

Micro-apartments Are in Vogue Today. But in Japan, People Have Been Living in the Nakagin Capsule Tower’s 100-square-foot Housing for Decades

Some 45% of 18-24-year-olds in London said they would consider living in a micro-flat if that was in the “perfect” location. A micro-apartment, also known as a micro-flat, is a one-room, self-contained living space, usually purpose-built, designed to accommodate a sitting space, sleeping space, bathroom and kitchenette with a size of 4-10 square meters.

They are essentially modern versions of the British bedsit and are becoming popular in urban centers in Europe, Japan, Hong Kong and North America, as they represent a seemingly straightforward antidote to persistent affordable housing shortages in dense growing cities.

In fact, some micro-apartments are being marketed as cost-effective fashionable lifestyle products.

Hogarth Architects transformed a large one-room flat in London into a stylish apartment using a wood insert that creates a separated kitchen and loft. It’s essentially one big piece of furniture custom-made for the space.

Curved surfaces can make a small space even smaller. The ability to organise the rooms vertically is reduced. But Dutch architects Queeste Architecten have managed to give this 320-square-foot micro-flat a spacious feel using lots of white, with built-in furniture and storage.

Curved surfaces can make a small space even smaller. The ability to organise the rooms vertically is reduced. But Dutch architects Queeste Architecten have managed to give this 320-square-foot micro-flat a spacious feel using lots of white, with built-in furniture and storage.

That oh-so-unfunny joke about moving into the garden shed is now a reality for young Londoners.

The prototype of a portable 130sq ft eco-friendly micro house that comes with a fold-down bed, kitchenette and shower room.

The micro houses, by Ecodom, will be constructed off-site and delivered fully made within two months of ordering, so it couldn’t be simpler to drop it into place and move straight in.

Architect Peter Kostelov turned a small flat into a oak-lined tube. Kostelov removed all the walls from the center of the apartment and replaced them with glass so light could get from windows on one side to the balcony on the other.

Specht Harpman Architects have turned a penthouse with a high ceiling into a two-level apartment and even managed to fit in a small grassy terrace.

Housing Complex in Slovenia is a Series of Honeycomb Modular Apartments

When it was built in 1972, architect Kisho Kurokawa’s Nakagin Capsule Tower was meant to be the housing structure of the future. Now in 2013, his “masterpiece” stands dilapidated and virtually empty.

Now here’s a solution that could revolutionize tiny spaces a slide-out system that turns a 350-square-foot space into 21 different rooms with bed, washing machine, entertainment, a bath covered by the bed when not in use, shelves, cabinets and more.

Do you believe higher density housing is the answer to London’s housing crisis as some believe or will it turn the city into Hong Kong and Shanghai?

9 Suggestions for Overcoming Barriers to Good Design When Using Modern Methods of Construction (Mmc)

The term ‘Modern Methods of Construction’ (MMC) embraces a range of technologies involving various forms of prefabrication and off-site assembly.

MMC is increasingly regarded as a realistic means of improving quality, reducing time spent on-site, improving on-site safety and addressing skills shortages in the construction of UK housing.

The variety of systems now available potentially allows the designer enough choice to sidestep problems deriving from constraints posed by the use of any one method. MMC systems, from closed-panel timber framed systems to bathroom pods are a palette from which designers can make choices. They are not necessarily stand-alone solutions that anticipate all the needs of an individual site and can be mixed and matched as appropriate.

These limitations are not obstacles to achieving the good design in MMC-based schemes, but may hinder the incorporation of more complex and innovative types of MMC from which greater overall benefits may be obtained which are considered under the following headings:

1. COST UNCERTAINTY

There is no doubt that, given products of comparable performance the key issue in purchases of MMC construction systems is the price. At present not enough is known about the potential costs of using volumetric and closed panel systems to enable confident specification at an early date. This inhibits designers from exploring the full potential of MMC systems. This is particularly true of the less repetitive, small, one-off scheme, where a smaller margin of benefits is gained from using MMC. The principal barrier to the uptake of MMC, therefore, seems to be the perception of cost uncertainty with respect to using more complex systems. Without doing substantial project-specific research, consultants and their clients simply do not know with enough degree of certainty how much the volumetric or closed panel systems are likely to cost, and what would be the savings to overall project costs produced by potential speed gains to offset against increased capital expenditure.

This is due to the complexity of assessing the ratio of cost of repetitive elements where pricing is relatively straightforward to the cost of adjusting elements or building in another method for the abnormal condition. Decisions to use innovative systems are likely to be made once designs are well progressed to enable teams to be more certain of costs. This can increase the potential for change or result in design compromise as the designer attempts to incorporate the specific limitations of a particular system in their design.

In an attempt to improve this situation, the MMC consultant and or clients could pull together a directory of MMC expanded to include cost comparison data. The huge range of variables involved inevitably makes this difficult, but a database of current construction cost information would be an invaluable resource.

2. PLANNING PROCESS AND EARLY COMMITMENT TO A SYSTEM

The time it can take to obtain planning permission has obvious implications both for project cost but also, in some circumstances, for architectural design innovation.

Most of the more complex types of MMC have an impact on dimensioning, the choice of external finish and detailing may have some effect on the buildings mass. Therefore, the construction system should be chosen prior to a planning application to avoid abortive work, redesign or amendment, or even resubmission for planning permission.

However, developers whose money is at risk, frequently hold off deciding on the construction technique until the last practicable moment, in order to get any advantage from fluctuations in material or component pricing.

Given the potential for lengthy duration of planning applications, this means that there is little incentive to prepare initial designs for planning with a prior decision to incorporate MMC firmly embedded. In cases where the developer has a financial or business link with the supplier, this is less likely to be the case. As the majority of commercial or residential developments involve some kind of arrangement with a developer, agreement on construction systems is often left to the stage after planning.

3. TIME INVESTMENT

Another very significant factor is the time investment required at the early stages of projects. This is needed to develop the design when the project is still at risk. There is a direct relationship between the scale and complexity of MMC component and the amount of time required to develop a design at an early stage.

The introduction of advanced or complex MMC techniques into the design process is potentially costly to the design team. A significant amount of research is needed to explore alternative systems, to obtain verification of suppliers’ credentials, investigate mortgage and insurance issues, visit previous sites, talk to system suppliers, obtain technical performance guidelines, understand junctions and interfaces, coordinate other consultants, obtain building control input and so on.

For a consultant, the only way of investing in this research is either through timely payment of increased fees by a visionary understanding client or through the anticipation of increased future productivity through repetition when a project is phased, or large enough, or likely to be followed by another similar project.

The potential of learning a system and then being able to repeat lessons learned efficiently is a powerful incentive for both client and consultant. By contrast, HTA’ s project at Basingstoke is an example of a phased project with a three to four-year duration allowed the design team to repeat various elements of the design, and the manufacturer to develop improved solutions to technical and supply problems.

4. INSUFFICIENT COMMUNICATION

Improved dialogue at the outset of the project is vital if design quality is to be maximised. Constraints and opportunities implicit within a particular system are more easily incorporated into design if partners communicate pre-planning. Increased early communication can be fostered through improved long-term partnering relationships.

Clients should also partner with a range of suppliers and architects so that choice and flexibility is not restricted.

5. INEXPERIENCE

Generally, the inexperienced client or design team will have to do more research, with the result that there is likely to be significant design development without a specific system being incorporated.

This is a disincentive to using a more complex system involving a higher proportion of MMC, where early decision making and knowledge of a system’ s capabilities have a decisive influence on the nature of the architecture. However, encouraging the take up of MMC through the use of a dedicated funding mechanism may assist clients in finding time for research into suitable MMC techniques.

6. SUPPLIER’S ROLE

Site capacity studies and early stage pre-planning design studies could be undertaken directly by system suppliers on behalf of clients, cutting out the usual procedure of commissioning design work by independent consultants.

7. ASSUMPTIONS

There are a number of assumptions that are generally held about certain types of MMC that may have been valid at one time but are no longer true today. There is a need for reliable and up to date information comparing system criteria, performance data, timescales, lead in times, capacity, construction time, sequencing issues, limitations, and benefits.

Therefore it would be helpful if a forum for discussion and experience exchange was set up.

8. DEMONSTRATING THE BENEFITS OF MMC

There is still a large amount of skepticism about the need to go very far down the line with MMC. This is reflected in the acceptance of the desirability of maintaining or indeed enhancing the pool of traditional craft skills throughout the UK.

A balanced view is that there is a demonstrable need for the wider use of MMC which is recognized by both industry and government. The best way for clients and the public generally to become more confident and knowledgeable about the quality of design achievable through MMC is to see it demonstrated.

9. FINANCIAL INCENTIVES

There is no doubt that spreading the burden of investment through the life of a project helps to ensure a higher standard of specification and hence quality. In the Netherlands, a ‘ Green Financing’ system has been developed by the Dutch government that provides favorable loan finance when certain sustainable standards are reached. In the UK, the Gallions HA has pioneered a study of this, based on a scheme in Thamesmead, ‘ the Ecopark project’.

Construction Begins on Sip Sports Center in Suzhou

Construction of the SIP Sports Centre has started in the Chinese city of Suzhou. The sports centre in Suzhou Industrial Park was designed by Ham burg’s star architects von Gerkan, Marg and Partner, and has been scheduled for completion in 2017.

The sports venue will be surrounded by residential quarters, a hotel and a leisure district offering community sports facilities and public spaces.

The development is being funded jointly by Sizhou City and Jiangsu Regional authorities and when complete, the complex will form part of the larger Suzhou Industrial Park.

Hamburg Architects Designs for China’s Garden City

A spokesperson for architects von Gerkan, Marg and Partners said: “Suzhou is famous in China for its landscape design, and the masterplan for this new sports park is based on this tradition and reputation. In a modern interpretation of the city’s traditional gardens, an informally designed park landscape flows around the podiums that rise in straight lines from the surrounding streets and support the stadiums.”

The beautiful conspicuous undulating roofs that on all three stadiums make the ensemble into a landmark visible from afar. As visitors walk along the curved pathways, various viewpoints open up to pavilion architecture, stunning water features, and a breathtaking landscape. Its curved silhouette stands out from the urban environment, blending harmoniously with the landscape and the park at the Xietang River. In addition, the succinct character of the stadiums is reinforced by a uniform façade design. The façades of both stadiums and the podiums are structured by horizontal lines, which follow the shape of the buildings in elegant curves.

The roof of the covered 15,000 capacity multi-purpose hall located to the north-east of the site is supported by v-shaped columns which provide a rhythm to the transparent glass façade of the hall.

The Heart of the Community

The multi-functional sports centre will include three national-standard venues includes a 45,000-seat stadium, an indoor pool with 3,000 seats and a 15,000-seat indoor arena. With its wide range of functions, the park has been designed to ensure a permanent and sustainable flow of visitors.

The facility is well connected to the Metro and offers the Suzhou residents not only a park, but also various shops for day-to-day needs, thus creating an attractive centre for the new part of the city.

MoVoCoSy – Modular Volumetric Construction System

New Urban Homes

A 3-dimensional system involving modules or pods which is the basic building block of much prefabricated construction. Several designers are experimenting with making this form adaptable to more than apartments. The majority of new high-density developments in London provide only flatted accommodation and ignore the needs of families. While the argument for more homes at a higher density is understood, should this policy exclude families? And what sort of city would London become?

For the past three years the architects have been examining opportunities for high-density urban family housing on a number of initiatives in Southwark, Ealing and Harrow. Using modular construction techniques the ‘courtyard’ homes deliver more space for less cost. Arranged in typical urban blocks and at no more than three storey densities they produce some 80 dwellings per hectare.

The house delivers flexible open plan ground floors with circulation spaces that are naturally lit. With both a courtyard and an upper terrace each house benefits from at least 40m2 of external space. More importantly this space is entirely private to the dwelling and is directly related to the kitchen, living and bedroom spaces. These are external rooms, a far cry for a patch of green, sandwiched between close boarded fencing and overlooked by the neighbours.

The five steel modules required for each house are delivered on low loaders and craned onto preprepared footings. All modules are fully fitted-out in the factory. The technology allows different fenestration arrangements, cladding options and roofing forms.

Architect: Proctor and Matthews

Principal Supplier: Spaceover